Graphene 3D printing: introduction and market status - Page 2

Versarien announces completion of construction phase of civil engineering project with Costain

Versarien has announced the completion of the construction phase of a civil engineering project being undertaken by the Company with a subsidiary of Costain Group.

Versarien has been working with Costain to develop designs for, and bring into production, a 3D printed concrete headwall for use in highway construction projects, part of the Digital Roads of the Future Partnership, a collaboration led by the University of Cambridge, Costain and National Highways, of which Versarien is a partner.

Various graphene technologies to be tested during moon and space missions

Graphene Flagship Partners University of Cambridge (UK) and Université Libre de Bruxelles (ULB, Belgium) collaborated with the Mohammed bin Rashid Space Centre (MBRSC, United Arab Emirates) and the European Space Agency (ESA) to test graphene on the Moon. This joint effort sees the involvement of many international partners, such as Airbus Defense and Space, Khalifa University, Massachusetts Institute of Technology, Technische Universität Dortmund, University of Oslo, and Tohoku University.

The MASER15 launch. Credit: John-Charles Dupin/Eurekalert

The Rashid rover is planned to be launched today (30 November 2022) from Cape Canaveral in Florida and will land on a geologically rich and, as yet, only remotely explored area on the Moon’s nearside – the side that always faces the Earth. During one lunar day, equivalent to approximately 14 days on Earth, Rashid will move on the lunar surface investigating interesting geological features.

Graphmatech and Wematter partner to develop graphene-enhanced materials for SLS 3D printing

Swedish graphene-solutions provider Graphmatech has partnered with 3D printer manufacturer Wematter to enhance polymer powders with graphene, to make them electrically- and thermally conductive, improve processibility, and more.

Together, the two startups will develop an electrically conductive powder, tailored for Gravity the SLS 3D printer by Wematter. The high-performance powder will enable Telecommunications, Aerospace and Automotive manufacturers to print parts with improved or maintained mechanical properties whilst achieving electrostatic dissipative (ESD), shielding, or even lower resistivity, performance.

Versarien launches Lunar 3D printed lifestyle pods

Versarien, an advanced engineering materials group and provider of graphene-enhanced cement admixture, recently announced the launch of its "Lunar" lifestyle pods. Lunar is Versarien's first 3D printed concrete product made with Cementene, Versarien's graphene-enhanced cement.

The launch involved Neill Ricketts, CEO of Versarien, unveiling a building printed with Cementene, at the Company's production facilities in Longhope, Gloucestershire. Known as Versarien Lunar, this is a milestone project for a 3D-concrete printed product with a graphene additive. The versatile pods can be used as an office, studio, gym, or leisure room. The pod's wall design shows the level of detail, flexibility and precision that can be achieved with 3D-concrete printing.

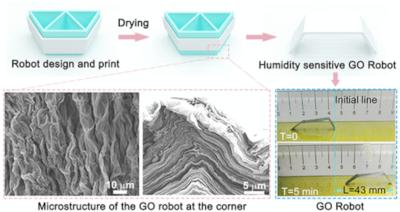

Researchers 3D print graphene-oxide soft robots

Researchers from China’s Harbin Institute of Technology have 3D printed a soft robot from graphene-oxide that is capable of moving backward and forwards when exposed to moisture.

The scientists combined Direct Ink Writing (DIW) 3D printing and constrained drying techniques to fabricate the soft robot, and were able to overcome the porosity, shrinkage and structure uniformity challenges previously observed when 3D printing graphene-oxide objects.

Advanced Graphene Products to go public next week at the NewConnect market

Poland-based Advanced Graphene Products S.A. (AGP), a graphene flakes and sheet developer, announced that it will go public, with a listing on the NewConnect market, on November 29th.

AGP has an annual capacity of 100Kg for graphene flakes and 150 m2 of large-area graphene sheets. The company is currently preparing to launch a pilot sale of a graphene-based filament for 3D printing.

Haydale launches next-gen graphene-enhanced 3D printing materials

A few years ago, several graphene producers released 3D printing materials enhanced with graphene. These materials enabled conductive non-metal materials, and enhanced the mechanical and thermal properties of these 3D printing filaments.

The market reaction, though, to these materials was cool. The materials did not provide a significant improvement, the price was high, and there were better alternatives available.

Researchers use 3D printing to make graphene aerogel flow-through electrodes for electrochemical reactors

Scientists at Lawrence Livermore National Laboratory (LLNL) are 3D printing graphene aerogel flow-through electrodes (FTEs), core components of electrochemical reactors used for converting CO2 and other molecules to useful products.

Benefiting from the design freedom afforded by 3D printing, the researchers demonstrated they could tailor the flow in FTEs, dramatically improving mass transfer the transport of liquid or gas reactants through the electrodes and onto the reactive surfaces. The work opens the door to establishing 3D printing as a viable, versatile rapid-prototyping method for flow-through electrodes and as a promising pathway to maximizing reactor performance, according to researchers.

3D printed graphene reinforced concrete trials to begin in train station

HS2 London tunnels contractor Skanska Costain Strabag JV (SCS JV) is to pioneer the on-site of 3D printing of graphene-reinforced concrete. The technology, called ‘Printfrastructure’, promises to bring big environmental benefits and cost savings, if deployed more widely.

First proof of concept trials are scheduled to begin in the spring, using 5 tonne computer-operated robots. These will initially be used to build part of the retaining walls for the mainline out of Euston station as well as materials stores on the project.

Researchers develop graphene aerosol gel inks for printing micro-supercapacitors

Researchers from Kansas State University, led by Suprem Das, assistant professor of industrial and manufacturing systems engineering, in collaboration with Christopher Sorensen, university distinguished professor of physics, have shown potential ways to manufacture graphene-based nano-inks for additive manufacturing of supercapacitors in the form of flexible and printable electronics.

The team’s work could be adapted to integrate supercapacitors to overcome the slow-charging processes of batteries. Furthermore, Das has been developing additive manufacturing of small supercapacitors â called micro-supercapacitors â so that one day they could be used for wafer-scale integration in silicon processing.

Pagination

- Previous page

- Page 2

- Next page