Graphene 3D printing: introduction and market status - Page 3

University at Buffalo team 3D prints graphene aerogels for water treatment

University at Buffalo (UB) researchers have developed a novel 3D printed water-purifying graphene aerogel that could be scaled for use at large wastewater treatment plants.

UB's 3D printed ultra-light G-PDA-BSA aerogel. Image credit: UB and 3dprintingindustry.com

UB's 3D printed ultra-light G-PDA-BSA aerogel. Image credit: UB and 3dprintingindustry.com

Composed of aerogel graphene and two bio-inspired polymers, the novel material is reportedly capable of removing dyes, metals and organic solvents from drinking water with 100% efficiency. Unlike similar nanosheets, the scientists’ design is reusable, doesn’t leave residue and can be 3D printed into larger sizes. The team now plans to commercialize its design for industrial-scale deployment.

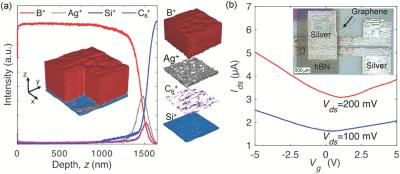

Researchers examine novel inkjet-printed graphene for high‐quality large‐area electronics

Researchers from the University of Nottingham’s Centre for Additive Manufacturing (CfAM) have reported a breakthrough in the study of 3D printing electronic devices with graphene.

Characterization of the fully inkjetâprinted graphene/hBN FET. Photo from article

Characterization of the fully inkjetâprinted graphene/hBN FET. Photo from article

The scientists utilized an inkjet-based 3D printing technique to deposit inks that contained flakes of graphene, in a promising step towards replacing single-layer graphene as a contact material for 2D metal semiconductors.

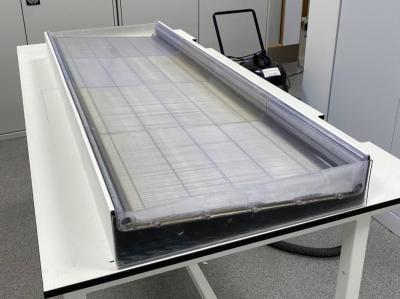

WMG and Senergy Innovations develop graphene-enabled all polymer solar thermal cell

Researchers led by Professor Tony McNally, from WMG, at the University of Warwick, in partnership with Senergy Innovations, have launched the first nanomaterial enabled all polymer solar thermal cell. This achievement was supported by funding from BEIS (Department for Business, Energy & Industrial Strategy).

The thermal properties of the polymers that were used were modified to enable heat from sunlight to be transferred with high efficiency to heat water in a low cost and sustainable way. The modular design of the cells reportedly allows for the rapid construction of a solar thermal cell array on both domestic and industry roofing.

Archer Materials announces proof-of-concept cartridge components for graphene biosensor device

Archer Materials has progressed its graphene-based biosensor technology development by successfully prototyping key device hardware using additive manufacturing (3D printing).

Graphene-based biosensor devices 2D printed on a circuit board that has been incorporated into the custom-designed and 3D printed cartridge made from ABS. The cartridge is opened and the interior is shown.

Graphene-based biosensor devices 2D printed on a circuit board that has been incorporated into the custom-designed and 3D printed cartridge made from ABS. The cartridge is opened and the interior is shown.

The cartridges were reportedly printed using acrylonitrile butadiene styrene (ABS), a robust engineering plastic, in less than 2 hours and with low costs, with the cartridges weighing about 13 grams (similar to a AAA battery) and measuring a few centimetres in size (palm size).

Researchers 3D print graphene-based electrodes that can detect toxins in food

A team of researchers from Nanyang Technological University, University of Chemistry and Technology Prague, and the King Saud University have 3D printed graphene-based electrodes capable of detecting mycotoxin zearalenone (aka ZEA, poisonous secondary metabolites) in food. The scientists believe their study could pave the way for a novel method of food safety assurance.

According to the study, contaminated products can lead to cancer or even death in humans. For this reason, timely and reliable methods of detecting mycotoxins are crucial for food inspectors to mitigate the spread and keep the products in food storage facilities safe until they reach the shelf.

ZEN Graphene Solutions announces collaboration with UBC-O on Department of National Defense project

ZEN Graphene Solutions has announced it will be launching a new research collaboration with Prof. Mohammad Arjmand and his team at the University of British Columbia (UBC)â€Okanagan Campus, with a $200,000 Department of National Defence (DND) Innovation for Defense Excellence and Security (IDEaS) award.

ZEN Graphene Solutions has announced it will be launching a new research collaboration with Prof. Mohammad Arjmand and his team at the University of British Columbia (UBC)â€Okanagan Campus, with a $200,000 Department of National Defence (DND) Innovation for Defense Excellence and Security (IDEaS) award.

ZEN will be providing in-kind contributions of Albany Pure materials and consultation with its technical team.The goal of this collaborative research project is to develop electrically conductive, molded and 3D printed graphene/polymer nanocomposites as more versatile replacements for metallic electromagnetic shields that are currently in use.

Texas State scientists design graphene-based antennae for NASA space programs

Associate professor of engineering at Texas State University,Dr. Maggie Chen, has been researching and studying durable, flexible electronic circuits in hopes of creating new antennas for NASA space travel programs. Chen’s work is expected to eventually replace the common use of silver materials in antennas. Ideally, Chen’s 3D-printed antennas would use graphene.

With the antennas, our goal is to reduce the volume and weight of the antennas and to provide and implement a more efficient approach to the use of antennas in space, Chen said. The idea is we roll the antennas up, launch a satellite into space and pop them back out when in space so they can communicate with the stations on the ground.

XG Sciences and Terrafilum collaborate to develop graphene-enhanced 3D printing filament

XG Sciences, designer and manufacturer of graphene nanoplatelets and advanced materials containing graphene nanoplatelets, and Terrafilum, an eco-friendly, high quality filament producer for the 3D printing industry, announced a joint development agreement to develop, produce and market 3D printing filaments and coatings using graphene-based materials.

XG Sciences, designer and manufacturer of graphene nanoplatelets and advanced materials containing graphene nanoplatelets, and Terrafilum, an eco-friendly, high quality filament producer for the 3D printing industry, announced a joint development agreement to develop, produce and market 3D printing filaments and coatings using graphene-based materials.

Chris Jackson, President of Terrafilum, points out, "The full potential for 3D printing is starting to be unlocked. The addition of XG's graphene formulations into our eco-friendly filaments will transform products allowing a greater variety of parts to be created at faster production rates using less energy."

Aecom uses graphene by Versarien to 3D print an arch that may modernize transport networks

Global infrastructure services firm Aecom is reportedly developing one of the UK’s first 3D-printed commercial products made from graphene-reinforced polymer.

The CNCTArch is being tested in Bristol (Photo from Aecom)

The CNCTArch is being tested in Bristol (Photo from Aecom)

Aecom has produced a graphene arch using additive manufacturing techniques. It believes the method could reduce the time and cost of installing digital signalling systems and transform the digitization of transport networks. The 4.5-meter high, lightweight arch is being tested on outdoor track at Network Rail’s workforce development center in Bristol.

GrapheneCA enters MoU with Apis Cor to develop a graphene-enhanced 3D printing system

GrapheneCA, graphene producer and developer of graphene-based technology for industries and consumers, has announced that it has signed a memorandum of understanding with Apis Cor to develop a 3D printing system capable of printing graphene materials.

GrapheneCA and its partner Apis Cor, a developer of specialized concrete 3D printing equipment, are discussing a future co-operation in which GrapheneCA will design an extruder and mixing system that can be embedded into Apis Cor’s 3D printer. Together, the two companies are expecting to develop a 3D printing system capable of printing graphene material.

Pagination

- Previous page

- Page 3

- Next page