Graphene batteries: Introduction and Market News - Page 3

NanoGraf begins production at scale to provide Military with better batteries

NanoGraf, an advanced battery material company, announced earlier this month the successful completion of the first large volume production run of its M38 18650 cell for the U.S. military.

Nanograf, formerly called SiNode Systems, pursues advances in Lithium-ion battery anodes for a wide range of industries from consumer electronics to electric vehicles. NanoGraf explaines that it uses a proprietary silicon alloy-graphene material architecture to overcome the silicon anode technical hurdles. The combination of silicon-based alloys and a flexible 3D graphene network helps stabilize the active material during charge and discharge. The company’s manufacturing process is different from others that rely on expensive and complex vapor deposition-based systems. Instead, a wet chemistry process has been developed that is highly scalable and already proven in a multi-ton-scale pilot manufacturing line in Japan. The anode material drops into existing electrode mixing and coating equipment and has been validated in large-scale battery manufacturing facilities.

Luxembourg Future Fund 2 announces equity investment into Lyten

Lyten and the Luxembourg Future Fund 2 (LFF2) have announced that LFF2 has made an equity investment into Lyten.

The investment in Lyten follows the signing of a Memorandum of Understanding (MOU) in October 2023 to establish Lyten’s European headquarters in Luxembourg. The investment highlights Luxembourg’s commitment to advancing clean technologies and incorporating them into the European economy. Through this partnership, Lyten and Luxembourg will collaborate on research and development and the introduction of several Lyten products into the European market including its lithium-sulfur EV battery.

SalgenX announces process that turns dendrites into high-performance cathode materials

Salgenx, developer of graphene-based salt water flow battery technology, has announced the development of a method to transform dendrites into a key component for high-performance cathode metallic materials in the saltwater flow battery.

This new approach aims to not only mitigate the problems caused by dendrites but to also leverage their unique properties to enhance battery efficiency and longevity.

Indian EV startup iVOOMi launches electric scooter with graphene battery

An India-based EV startup called iVOOMi has launched the S1 Lite, an electric scooter available with two battery options, Graphene and Li-ion.

The graphene unit offers a range of up to 75 km and takes 7-8 hours to charge fully, while the Li-ion pack provides a range of up to 85 km and can be charged in under 4 hours. Both variants feature a 1.2 kW motor with 1.8 kW peak power and 10.1 Nm of torque.

Solidion plans to expand production capacity of silicon-rich graphene composite materials

Solidion Technology, an advanced battery technology solutions provider, has announced its plan to begin expanding the production capacity of silicon-rich graphene composite materials in early 2025.

The amount of energy that a lithium-ion battery can supply to an electric vehicle (EV) is limited by the amount of charges stored in its anode and cathode materials. Although graphite has been the preferred anode material during the past 30 years, silicon oxide (SiOx) and silicon (Si) are two evolving anode materials capable of improving the energy density of EV batteries and extending the EV range by 20-40%. However, the higher-capacity gain of both silicon and silicon oxide is limited by the technical issue of large volume change-induced rapid capacity decay and processing difficulty. Solidion has targeted this technical obstacle and has established a Dayton, Ohio-based facility for manufacturing silicon oxide (SiOx) and silicon (Si). The Solidion team is ready to expand the production capacity for these two types of high-capacity anode materials.

Graphene-Info updates its Graphene Batteries Market Report

Today we published a new edition of our Graphene Batteries Market Report, with all the latest information and updates from companies and researchers in the field. The batteries market is extremely active, as demand from EVs and mobile applications increases R&D efforts, and graphene is seen as a potential material to increase capacity, decrease charging times and improve other performance metrics.

Reading this report, you'll learn all about:

- The advantages of using graphene in batteries

- The different ways graphene can be used in batteries

- Various types of graphene materials

- What's on the market today

The report package also provides:

- A list of all graphene companies involved with batteries

- Detailed specifications of graphene-enhanced anode materials

- Personal contact details into most graphene developers

- Free updates for a year

This Graphene Batteries market report provides a great introduction to graphene materials used in the batteries market, and covers everything you need to know about graphene in this niche. This is a great guide for anyone involved with the battery market, nanomaterials, electric vehicles and mobile devices.

Researchers design graphene-based thermal regulator that enable safer lithium-ion batteries

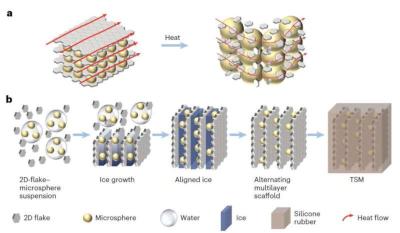

Researchers at Tsinghua University, Zhejiang University and Zhejiang Sanhua Intelligent Controls Co., have designed a graphene-based thermal-switching material for improving the safety of lithium-ion batteries (LIBs) by making sure that they can safely operate at different temperatures and do not explode when overheated.

a) Thermal-switching mechanism of the TSM. b) The self-assembly process through freeze-casting of 2D-flake–microsphere suspensions to form an alternating multilayer scaffold together with polymer infiltration. Image credit: Nature Energy

A general approach to improving the safety of LIBs is using thermal-conducting interlayers, materials designed to even out the temperature between a battery's modules, bringing it to between 15 to 45 °C. To ensure that a high-capacity LIB is safe, these materials should be highly thermally insulating, thus preventing the propagation of heat, while also ensuring that temperature is uniformly distributed in the battery. The research team's newly developed thermal-switching material meets both criteria, and can effectively regulate the temperature in high-capacity batteries. This material rapidly responds to temperature, enabling the safe cycling of batteries in varying operating conditions.

Lyten ships Li-S battery A-samples for customer evaluation

Lyten has announced it has shipped A samples of its 6.5 Ah (C/3 discharge rate, 25° C) lithium-sulfur pouch cells to Stellantis and other leading US and EU automotive OEMs for evaluation. Lyten is known for using Li-S cathode made of sulfur and its proprietary 3D Graphene, sourced by capturing carbon from methane. This is said to eliminate the need for critical minerals like nickel, cobalt, and manganese in the cathode. The Li-S anode is a lithium metal composite, eliminating the need for graphite. The Company explaines that elimination of critical minerals means a projected 65%+ lower carbon footprint than lithium-ion batteries and a supply chain that can be fully sourced in the US or EU at scale.

Lyten manufactures lithium-sulfur cells in both pouch and cylindrical formats (2170 and 18650) and is currently shipping the 6.5 Ah pouch cell format for customer evaluation. Later this year, Lyten plans to deliver cylindrical A samples for evaluation. Lyten’s lithium-sulfur format flexibility enables its use in a wide range of industries beyond automotive, including space, aerospace, drones, micromobility, defense and consumer electronics.

Researchers use self-organized crack-free nanocellular graphene film to enhance sodium ion batteries

Researchers from Tohoku University, Tianjin University of Technology, Pohang University of Science and Technology and Johns Hopkins University recently designed a nanocellular graphene (NCG) film through the self-organization of carbon atoms using liquid metal dealloying and employing a defect-free amorphous precursor.

The flexible freestanding nanocellular graphene film. Image credit: Advanced Materials

Nanocellular graphene is a specialized form of graphene that achieves a large specific surface area by stacking multiple layers of graphene and controlling its internal structure with a nanoscale cellular morphology. NCG is attractive thanks to its potential to improve the performance of electronic devices, energy devices and sensors. However, its development has been hindered by defects that occur during the manufacturing process. Cracks often appear when forming NCG, and scientists are looking for new processing technologies that can fabricate homogeneous, crack-free and seamless NCGs at appropriate scales.

GMG secures funding to build graphene aluminum ion battery pilot plant

Graphene Manufacturing Group (GMG) has secured Queensland government backing for a proposed automated battery pilot plant for the manufacture of GMG’s Graphene Aluminum Ion Battery. The Company signed a Queensland Critical Minerals and Battery Technology Fund Agreement with the state for a grant of AUD$2 million (almost USD$1,300,000).

GMG is using graphene to produce aluminium-ion batteries utilizing a patent-pending surface perforation technology developed by the University of Queensland. GMG said the grant was for the payment of 50 percent of the capital cost of GMG’s proposed pilot plant, up to a maximum of $2 million.

Pagination

- Previous page

- Page 3

- Next page