Graphene Coating: introduction and market status - Page 7

Haydale announces project with Viritech to develop graphene-enhanced epoxy resins for hydrogen storage vessels

Building on the Memorandum of Understanding (MOU) signed with Viritech in September 2021, Haydale, has announced the next phase with the cleantech engineering company to develop nano-enhanced epoxy resins for hydrogen storage vessels.

The £97,750 Storage of Hydrogen and Nanomaterial Enhancement ('SHYNE') project will run for an initial period of seven months, starting in March.

AGP signs a cooperation agreement with Garmor

Poland-based Advanced Graphene Products has signed a cooperation agreement with U.S-based Garmor, a division of Asbury Carbons, aiming to increase the scale of operations and expand its markets.

Advanced Graphene Products entered the Warsaw NewConnect market at the end of November last year. The company has an annual production capacity of 100kg of graphene flakes and 150m2 of single-crystal graphene sheets. This production capacity will allow commercialization of the developed graphene applications on an industrial scale.

Researchers wrapped droplets in graphene for better sensors, microchips and batteries

Researchers from the University of Sussex, the University of Brighton and CNRS have developed a way to wrap emulsion droplets with graphene and other 2D materials by reducing the coatings down to atomically-thin nanosheet layers. The team said this could ‘significantly advance’ the new technology area of liquid electronics, enhancing the functionality and sustainability of potential applications in printed electronics, wearable health monitors and even batteries.

The scientists were able to create electrically-conducting liquid emulsions that are the lowest-loading graphene networks ever reported just 0.001 vol%. This means that the subsequent liquid electronic technology will be both cheaper and more sustainable because it will require less graphene or other 2D nanosheets coating the droplets.

Indian company launches new coating based on graphene dispersions by Applied Graphene Materials

Applied Graphene Materials (AGM) has announced that Stanvac-Superon Group, an India-based manufacturer of industrial repair and maintenance solutions, has launched a conductive coating incorporating AGM’s Genable graphene dispersions, for use on industrial power transmission equipment.

Following successful development and testing, the new protective, conductive coating incorporating AGM’s A-GNP35 graphene dispersions will reduce contact resistance in coated copper and aluminium electrical cable joints to reduce the power lost over the connection.

Applied Graphene Materials' graphene-enhanced anti-corrosion primer used by England’s Environment Agency for flood defense applications

Applied Graphene Materials has announced that England’s Environment Agency (EA) has successfully completed its first application of AGM’s harsh environment anti-corrosion product to one of its flood defense assets on the North East coast of England. The coastal flood defense gates were coated with AGM’s new graphene-enhanced Genable CX-based anti-corrosion primer.

The AGM’s coating system used in this project is a further iteration of AGM’s product offerings for barrier performance and anti-corrosion application. It represents the culmination of 18 months of in-depth testing and evaluation of anti-corrosion performance for both salt-spray and immersion in harsh test regimes.

Tata Steel develops a unique few-layer rGO film material

Tata Steel has developed a new product, a few-layer film of rGO along with its collaborators at CeNS, Bengaluru. The company is now starting to mass-produce the films and offer them to application developers.

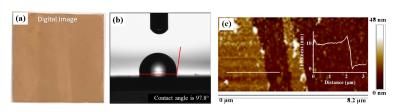

Figure 1: (a) Digital image of rGO/Cu foil (5 cm2). Contactact angle (b) and AFM height profile (c) on rGO/Cu

The rGO film is produced (using a modified CVD process) on copper. The film's average thickness is 5-10 nm and offers a corrosion rate of 0.02 mm/year (Tafel) and a water contact angle of ~ 97°.

These unique properties make the film suitable to protect the copper from corrosion, chemical attacks, and thermal oxidations. It also makes copper hydrophobic and can act as an antibacterial surface.

Applied Graphene Materials launches new graphene-enhanced range of coatings, paints and additives

Applied Graphene Materials (AGM) has announced the introduction of two new products based on its GNPs.

The Company has launched a range of industrial anti-corrosion paint incorporating its Genable graphene additives. The two epoxy-based prototype primer systems are said the AGM to represent an easy way for those considering the adoption of graphene to quickly test and evaluate its potential benefits.

Graphene and hBN nano-additives improve eco-friendly lubricant oils

Researchers from the University of Nevada have investigated the introduction of graphene nanoplatelets (GNPs) and hexagonal boron nitride (hBN) to canola oil to improve its tribological properties, as part of an effort to reduce the usage of lubricants based on petroleum as lubricants for reducing abrasion and friction.

Three nanoscale lubricating combinations were created by combining both GNP and hBN settings in varied ratios to get the best beneficial synergy. The team reports that lubrication quality and performance may be increased by using low-weight percentages of nanoparticle (NP) and microparticle additions. One benefit is that it has a reduced coefficient of friction (COF) and wearing.

Sparc Technologies reports successfull testing of graphene-enhanced epoxy coatings

In 2020 Sparc Technologies acquired Graphene Technology Solutions (GTS) and announced plans to become a significant developer of graphene-based products".

Sparc announced today that after six months of testing, its graphene-based additives was found to offer up to 40% improvement in the anti-corrosive performance of atmospheric epoxy coatings. The company used commercially available epoxy coatings available from leading coatings manufacturers.

GIT's graphene coating to be tested on large ships

Graphite Innovation and Technologies (GIT) uses graphene as the base for its strong, slippery and non-toxic hull paint. The coating helps prevent marine fouling when aquatic organisms such as barnacles stick to the hull thus improving the flow of water against the vessel, making it more efficient. Now, the coating will be heavily tested on large vessels operated by Oceanex and Baffin Fisheries.

The vessels operated by Oceanex and Baffin Fisheries are larger vessels that move at a much higher speed than the small inshore fishing vessels previously tested under our contract with Transport Canada, said Mo AlGermozi, President of Graphite Innovation and Technologies. It is so much more comparable to the large transport vessels that we target as key customers, as transport fleets are more interested in reducing fuel costs and improving their environmental impact.

Pagination

- Previous page

- Page 7

- Next page