Graphene composites: introduction and market status - Page 4

Graphene Innovations Manchester and Space Engine Systems to collaborate on graphene-enhanced hypersonic applications for space travel

UK-based Graphene Innovations Manchester (GIM) and Space Engine Systems (SES) from Canada have signed a Memorandum of Understanding (MoU) to collaborate in various areas of SES’s Hello series of Aerospace and Space vehicles, focusing on using graphene for hypersonic applications.

GIM is working on the development and commercialization of advanced graphene-based solutions for composites, particularly in Graphene Space Habitat,

and also Type V hydrogen storage tanks. GIM is the largest Tier 1 partner in the Graphene Engineering Innovation Centre (GEIC) at the University of Manchester.

Sparc Technologies and Swinburne University team up to advance graphene coatings and composites

Swinburne University of Technology and Sparc Technologies recently announced a collaboration, spearheading the evolution of smart coatings and composites through the Australian Research Council (ARC) research project. The partnership aims to revolutionize key industries, including aerospace, infrastructure, renewable energy, and more.

Sparc Technologies' state-of-the-art facility enables the mass production of its graphene additive, Ecosparc. Denis Wright, general manager of Graphene Materials at Sparc, stating: “It is a very exciting opportunity to be contributing to this project and developing Ecosparc additives that will impart through their intrinsic properties, intelligence into coatings and composites.”

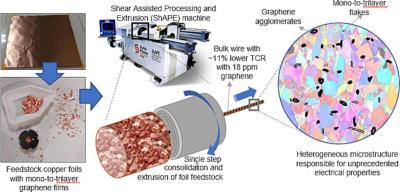

Researchers design copper-graphene composites with improved electrical conductivity

Researchers from North Carolina State University and Pacific Northwest National Laboratory (PNNL) recently used shear assisted processing and extrusion (ShAPE) to synthesize macro-scale copper-graphene composites with a simultaneously lower temperature coefficient of resistance (TCR) and improved electrical conductivity over copper-only samples.

The team's new graphene-copper composite with an improved ability to conduct electricity could lead to more efficient electricity distribution to homes and businesses, as well as more efficient motors to power electric vehicles and industrial equipment. The team has applied for a patent for the work, which was supported by the Department of Energy (DOE) Advanced Materials and Manufacturing Technologies Office.

Researchers develop self-assembling graphene sensors for modular wearable electronics

Researchers at Peking University, University of Science and Technology Beijing and Peking University Third Hospital have reported magnetically self-assembling graphene sensors.

While wearable sensors can provide continuous, personalized health tracking beyond clinical visits, most devices today still have fixed designs targeting single applications, lacking versatility to address users' changing needs. The team's recent work could address this issue and enable modular, reconfigurable wearable electronics customized to individuals.

Black Swan Graphene enters agreement with Hubron International

Black Swan Graphene has announced a commercial agreement with Hubron International, specializing in customized solutions in plastic masterbatch and conductive compound manufacturing. This strategic partnership is set to fast-track the commercialization of Black Swan's graphene products, leveraging Hubron's 80 years of compounding expertise and market access.

Hubron specializes in black masterbatch production with over 85% of its products exported worldwide. Hubron and Black Swan will explore opportunities to incorporate the use of graphene-enhanced masterbatch for improved functionality where commercially and technically possible. Hubron will also play a crucial role in the manufacturing of graphene enhanced black masterbatch for commercial applications. Black Swan, in turn, will be a preferred provider of graphene for such manufacturing endeavors.

Researchers examine brucite/graphene composites for improved electronics

Researchers at the University of Bologna have introduced and considered a single layer of brucite Mg(OH)2, a 2D material that can be easily produced by exfoliation (like graphene from graphite), for the creation of van der Waals composites (known as heterostructures, or heterojunctions), where two monolayers of different materials are stacked and held together by dispersive interactions.

First principles simulations showed that brucite/graphene composites can modify the electronic properties (position of the Dirac cone with respect to the Fermi level and band gap) according to the crystallographic stacking and the presence of point defects. This could be meaningful for various applications, such as electronics.

Blacklidge uses proprietary graphene composites to develop next-generation asphalt

Blacklidge Emulsions, a Mississippi-based company that develops asphalt technology, recently announced that it is developing next-generation asphalt products enhanced with graphene. The developement will be done through a collaboration between Blacklidge and TLC Products. The two companies are combining their respective niche expertise to further the performance, safety and sustainability of asphalt pavement throughout the U.S. and the rest of the world.

“A little bit goes a long way,” says Charles Chang, founder of TLC. “Our patented process, licensed from Rutgers University, produces covalent bonded graphene mixed with various polymers to dramatically improve their mechanical properties. We use graphite and recycled plastics as raw materials, opening a new path to bring low-cost graphene to industries like asphalt in ways never thought possible on such a broad scale”. Among other benefits, TLC’s graphene-composites will absorb ultraviolet light from the sun and reduce degradation of the organic components of the “glue” that holds asphalt together –– often the weakest link contributing to pavement breakdown.

Copper-graphene composites could lead to better electrical wires and motors

Researchers at North Carolina State University and Pacific Northwest National Laboratory have found that graphene can enhance an important property of metals called the temperature coefficient of resistance.

They showed that mixing graphene in just the right proportion with copper could lead to improved electrical wires for more efficient electricity distribution to homes and businesses, as well as more efficient motors to power electric vehicles and industrial equipment. The team has applied for a patent for the work, which was supported by the Department of Energy (DOE) Advanced Materials and Manufacturing Technologies Office.

Directa Plus enters deal for system to be used for graphene compounds

Directa Plus has revealed that it has signed a deal with an unnamed Italian innovator to buy the technology for a system capable of preparing tailored graphene compounds. According to the Company, this technology will initially be used in batteries and polymers.

It explained that the acquired know-how and technology would help to enable the dry encapsulation of G Plus graphene nanoplatelets into different compound carriers for different exacting applications.

Directa Plus announces expansion of collaboration with Miguel Caballero

Directa Plus has announced a significant expansion of its collaboration with CIA Miguel Caballero, a prominent manufacturer of bulletproof vests and personal protective equipment (PPE).

Directa Plus began collaborating with CIA Miguel Caballero in July 2022, supplying advanced graphene-based textile solutions that enhance the performance and comfort of bulletproof vests. The collaboration is reportedly entering a new phase of growth, solidifying the Group's position as a partner in CIA Miguel Caballero's product innovations.

Pagination

- Previous page

- Page 4

- Next page