Graphene Oxide: Introduction and Market News - Page 6

Graphene-Info updates all its graphene market report

Today we published new versions of all our graphene market reports. Graphene-Info provides comprehensive niche graphene market reports, and our reports cover everything you need to know about these niche markets. The reports are now updated to April 2022.

The Graphene Batteries Market Report:

- The advantages using graphene batteries

- The different ways graphene can be used in batteries

- Various types of graphene materials

- What's on the market today

- Detailed specifications of some graphene-enhanced anode material

- Personal contact details into most graphene developers

The report package provides a good introduction to the graphene battery - present and future. It includes a list of all graphene companies involved with batteries and gives detailed specifications of some graphene-enhanced anode materials and contact details into most graphene developers. Read more here!

Researchers shed light on the behavior of graphene oxide at extreme temperatures

Researchers from Moscow Institute of Physics and Technology, Joint Institute for High Temperatures of the Russian Academy of Sciences, Skolkovo Institute of Science and Technology, Saint Petersburg State Marine Technical University, Institute of Nanotechnology of Microelectronics of the Russian Academy of Sciences, Lomonosov Moscow State University, Bauman Moscow State Technical University and Emanuel Institute of Biochemical Physics of the Russian Academy of Sciences have found the reason why instead of burning down at high temperatures, graphene oxide opens the door to a promising and inexpensive graphene production method.

The search for a cheap and efficient route of graphene fabrication is still ongoing. Graphene reduction from graphene oxide by laser irradiation appears as a promising route: with graphene oxide produced from ordinary graphite using chemical methods, the laser-aided reduction technique holds much promise in terms of cost and controllability of the resulting material quality.

Researchers develop a graphene oxide aerogel foam to improve all solid state lithium batteries

Researchers from China's Jiangsu University and Changzhou University have developed a non-ceramic solid-state electrolyte based on a graphene oxide (GO) aerogel framework filled with polyethylene oxide.

Li-ion batteries currently perform a key role in electric cars, but contain combustible liquid electrolytic materials which may pose major safety issues. The solid-state electrolyte (SSE) can replace the standard organic liquid electrolyte and is predicted to address safety issues such as leaking, heat runaway, and even explosions during operation.

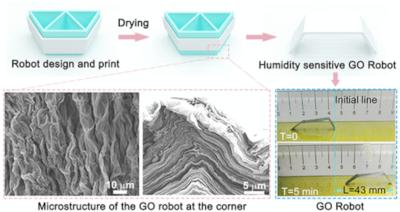

Researchers 3D print graphene-oxide soft robots

Researchers from China’s Harbin Institute of Technology have 3D printed a soft robot from graphene-oxide that is capable of moving backward and forwards when exposed to moisture.

The scientists combined Direct Ink Writing (DIW) 3D printing and constrained drying techniques to fabricate the soft robot, and were able to overcome the porosity, shrinkage and structure uniformity challenges previously observed when 3D printing graphene-oxide objects.

Graphene-Info updates all its graphene market report

Today we published new versions of all our graphene market reports. Graphene-Info provides comprehensive niche graphene market reports, and our reports cover everything you need to know about these niche markets. The reports are now updated to January 2022.

The Graphene Batteries Market Report:

- The advantages using graphene batteries

- The different ways graphene can be used in batteries

- Various types of graphene materials

- What's on the market today

- Detailed specifications of some graphene-enhanced anode material

- Personal contact details into most graphene developers

The report package provides a good introduction to the graphene battery - present and future. It includes a list of all graphene companies involved with batteries and gives detailed specifications of some graphene-enhanced anode materials and contact details into most graphene developers. Read more here!

G6 Materials announces testing agreement of GO materials with U.S. Army

G6 Materials has announced that its wholly owned subsidiary, Graphene Laboratories (GLI), has entered into a Testing Services Agreement (the TSA) with the U.S. Army Engineer Research & Development Center (U.S. Army ERDC) in Vicksburg, Mississippi.

GLI will be assessing the performance characteristics and quality of graphene oxide (GO) materials in order to help solve environmental challenges. Development of GO materials with superior adsorptive capabilities for the removal of complex contaminants will take place, with 10 specific tests to be conducted by the U.S. Army ERDC on GLI’s GO materials. The project will run for an expected time frame of one year.

Tata Steel develops a unique few-layer rGO film material

Tata Steel has developed a new product, a few-layer film of rGO along with its collaborators at CeNS, Bengaluru. The company is now starting to mass-produce the films and offer them to application developers.

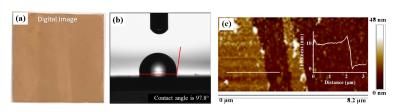

Figure 1: (a) Digital image of rGO/Cu foil (5 cm2). Contactact angle (b) and AFM height profile (c) on rGO/Cu

The rGO film is produced (using a modified CVD process) on copper. The film's average thickness is 5-10 nm and offers a corrosion rate of 0.02 mm/year (Tafel) and a water contact angle of ~ 97°.

These unique properties make the film suitable to protect the copper from corrosion, chemical attacks, and thermal oxidations. It also makes copper hydrophobic and can act as an antibacterial surface.

G6 Materials installs a new pilot-scale graphene oxide reactor

G6 Materials (Formerly called Graphene 3D Lab) has installed a new pilot-scale graphene oxide (GO) reactor at its Ronkonkoma New York facility.

G6M says that the new reactor increases the company’s GO production capacity five-fold. The first batch of graphene oxide from the New Reactor was produced on November 26, 2021.

Graphene oxide could improve aircraft fuel

A team of researchers at UBC Okanagan (UBCO), studying the burning rate of nanomaterials in liquid fuels, believe they have created a recipe for clean-burning, power-boosting aircraft fuel.

A droplet of fuel mixed with nanomaterials is ignited during an experiment in UBCO’s Combustion for Propulsion and Power Lab. Image credit: UBCO

A droplet of fuel mixed with nanomaterials is ignited during an experiment in UBCO’s Combustion for Propulsion and Power Lab. Image credit: UBCO

The team is investigating the combustion characteristics of microscopic graphene oxide inside fuel. Their experiment measures the ignition delay, burn rate and speed by which the graphene particles and fuel separate into smaller particles. Working with our industry partner, ZEN Graphene Solutions, we are assessing how the burn rate of this mixture can potentially improve its combustion properties, explains lead author and doctoral student Sepehr Mosadegh.

New GO–MnO2 nano-filter can efficiently clean water from toxic dyes

Researchers from Korea's University of Seoul, Russia's RUDN University and several India-based institutes have created a nano-filter for water purification from synthetic dyes. The graphene-based composite can reportedly remove up to 100% of harmful compounds from water, and it can be used up to seven times without losing efficiency. In addition, the synthesis of the nanofilter itself is economical and environmentally friendly.

Synthetic dyes are used in industrial chemistry and pharmaceuticals. They reach the wastewater together with other industrial waste and pollute the environment. Existing methods of water purification are not quite practical, as the proposed adsorbents are usually disposable and work slowly. Therefore, scientists continue to look for effective and eco-friendly solutions to this problem. The team in this recent work has proposed a reusable graphene-based nanocomposite that can quickly absorb dyes from water.

Pagination

- Previous page

- Page 6

- Next page