Graphene Manufacturing Group (GMG) has provided a progress update on its Graphene Aluminium-Ion Battery technology ("G+AI Battery") being developed by GMG and the University of Queensland ("UQ").

The Company is currently optimizing the G+AI Battery pouch cell electrochemistry. The challenges that the G+AI Battery are showing through this phase of its maturation are very similar to other battery chemistries that have been developed into mass production - including Lithium-Ion batteries. The performance of the pouch cells will be communicated upon successfully producing a repeatable and 3rd party tested 1000 mAh+ battery pouch cell.

The major components of the G+AI Battery are:

Cathode: Graphene, binder and solvent (water or another solution) layered on a metal foil cathode substrate.

Anode: Aluminium foil

Electrolyte: Aluminium Chloride and ionic fluid (Urea or another solution)

Separator: Separator

These are assembled in a standard step by step process - which is documented in the Company's operation manual of procedures for the Battery Development Process. Note that there are many different variations that can be trialed in a cell design.

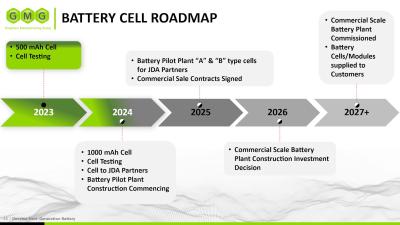

The Company previously announced in February 2024 it produced multiple battery pouch cells with over 1000 mAh (1 Ah) capacity. This was a major milestone achieved to demonstrate scalability from coin cells to pouch cells, and represented the next milestone in the battery's development.

GMG is also reviewing a potential investment for the procurement and installation of an automated pouch cell battery pilot plant in its Richlands Australia Facility. The Pilot Plant will enable the Company to produce pouch cells for potential customers to test in battery packs for different applications. Following the successful start-up of the Pilot Plant and successful customer trials, GMG expects to pursue large scale commercial production.

GMG stated that the battery technology readiness level ("BTRL") of the Graphene Aluminium-Ion technology remains at Level 4. GMG is currently optimizing electrochemical behavior for pouch cells via ongoing laboratory experimentation. If GMG invests, constructs and commissions a Pilot Plant it is anticipated that the battery technology will progress to BTRL 7 and 8 since the equipment and process needed to make the Graphene Aluminium-Ion batteries is the same as those employed to make Lithium Ion Batteries.

The Company says that it continues to see a broad range of applications for a completed GMG Graphene Aluminium Ion Battery - utilizing its ultra-high power-density and nominal energy density characteristics. Along with Rio Tinto, a range of global companies have reportedly confidentially expressed their interest in working with GMG in the following vertical sectors: aviation, EVs, diesel engine replacement, rail, energy storage, personal electronics and power tools.