Aligned bi-layer graphene cools down when hit by laser light

Researchers from the University of Manchester (with help from an international team of scientists) discovered that if you stack two graphene sheets on on top of the other (bi-layer graphene) in a certain way, it actually cools down when hit with laser light.

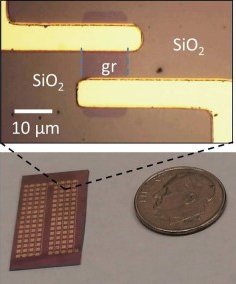

The two graphene sheets are aligned so one sheet is rotated by 11.3 degrees. With a specific laser energy, instead of heating up like any "normal" material - it cools down. The researchers explain that the photons of the laser absorb the vibration energy of the atoms - instead of the other way around.