Graphene composites: introduction and market status - Page 32

Applied Graphene Materials enters agreement to develop and commercialize a new graphene ink technology

Applied Graphene Materials has outlined details of a new graphene-enhanced ink technology and signed a development deal with the University of Sheffield Advanced Manufacturing Research Center. A patent for this new development, called Structural Ink, has been registered and once fully commercialized, the product will be targeted at the advanced composites industry.

Applied Graphene Materials has outlined details of a new graphene-enhanced ink technology and signed a development deal with the University of Sheffield Advanced Manufacturing Research Center. A patent for this new development, called Structural Ink, has been registered and once fully commercialized, the product will be targeted at the advanced composites industry.

The technology will aim to enable users to increase mechanical toughness, through the addition of graphene. This is ultimately designed to improve performance, enable further weight reduction and reduce total manufacturing costs.

Talga reports impressive concrete strength test results using its graphene

Australia-based technology minerals company, Talga Resources, recently announced impressive initial concrete prototype strength results from trials undertaken at the commercial concrete/cement laboratory of Betotech Baustofflabor in Germany.

Australia-based technology minerals company, Talga Resources, recently announced impressive initial concrete prototype strength results from trials undertaken at the commercial concrete/cement laboratory of Betotech Baustofflabor in Germany.

Graphene and graphite enhanced cement and concrete are key priority product targets for Talga. Concrete test prototypes were formulated with Talga graphene and graphite additives combined with a European industry cement and aggregate mixture. Results from the trial showed significant increases, about 26% in flexural strength and 14% in compressive strength, using Talga materials over reference concrete at 28 days cure time.

Haydale to collaborate with Nanospan on graphene-based composites

Haydale Graphene Industries recently stated that it has entered a memorandum of understanding with Nanospan India to collaborate on developing advanced nano composites for the Indian market.

Haydale Graphene Industries recently stated that it has entered a memorandum of understanding with Nanospan India to collaborate on developing advanced nano composites for the Indian market.

Nanospan, a graphene application development firm based in India, will work with Haydale to develop composites focused on the defence, aerospace and energy sectors in India.

Zenyatta Ventures announced successful testing of its material in Si-G anodes for Li-ion batteries

Zenyatta Ventures has announced the successful testing of its graphene oxide material by a U.S. based advanced materials company developing silicon-graphene anodes for the next generation of lithium-ion batteries.

Zenyatta Ventures has announced the successful testing of its graphene oxide material by a U.S. based advanced materials company developing silicon-graphene anodes for the next generation of lithium-ion batteries.

Zenyatta stated that preliminary results showed the ease of processing with its graphene oxide and similar electrochemical performance compared to the control material that is currently being used by the U.S. company. Zenyatta's high-purity graphite was recently converted to graphene oxide and then sent to the U.S. collaborator for testing as an advanced nano-material in a new Lithium-ion battery.

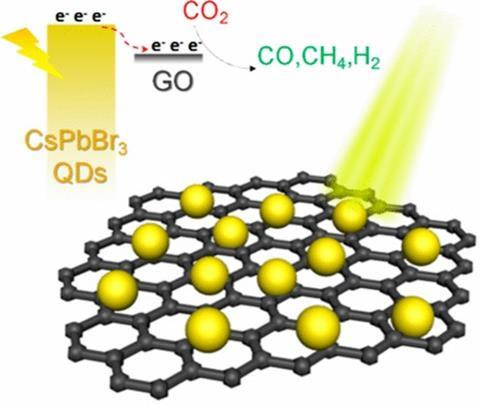

Graphene oxide combines with perovskite quantum dots to create artificial photosynthesis

Researchers from Sun Yat-Sen University in China have created a composite of graphene oxide and perovskite quantum dots that can reduce CO2 when stimulated with light. It is referred to as the first known example of artificial photosynthesis based on perovskite quantum dots and GO.

The team prepared quantum dots semiconductor nanoparticles of a highly stable cesiumlead halide perovskite, as well as a composite material made of these quantum dots and graphene oxide. Both materials showed an efficient absorption of visible light and strong luminescence. The team used these products to achieve a fundamental step in artificial photosynthesis the reduction of CO2. To simulate sunlight, they used a xenon lamp with an appropriate filter.

A new graphene center opened in Beijing, China

A graphene industry innovation center was recently established in Beijing, China. The center aims to become a world-class graphene composite technology research and industrial incubator hub.

Beijing Graphene Industry Innovation Center will take the advantage of Beijing's innovative resources to research and develop cutting-edge new materials. It hopes to speed up the transformation of scientific research achievements and enhance the graphene industry.

Updates from Prof. James Tour's graphene lab at Rice University

Prof. James Tour's research lab in Rice University is one of the leading graphene research groups in the world, with several key technologies first discovered and developed there. Professor Tour is involved with several application areas - from de-icing coating to energy storage and quantum dots production. Prof. Tour was kind enough to share his time and update us on the latest research and commercialization efforts at his lab.

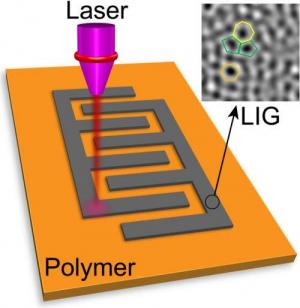

The Tour group is now commercializing two of its key technologies. First up is the laser-induced graphene (or LiG), which was reported first in 2014. This is a process in which graphene is formed on a flexible polyimide film using a room-temperature laser-based process. It is possible to pattern this graphene to create devices and as it is formed on a flexible film this easily enables flexible electronics applications.

Sir Richard Branson excited about graphene's future in aerospace

In a recent speech, Virgin Atlantic president Sir Richard Branson raised the prospect of planes being made entirely from graphene within 10 years. Counting on graphene's mechanical strength and light nature, he hopes the aerospace industry could welcome light, durable planes that will cut fuel expenses, among other advantages.

He was quoted saying "hopefully graphene can be the planes of the future. 10 years down the line. They would be massively lighter than the current planes, which again would make a difference on fuel burn." Branson likened the push for graphene planes to urging Airbus and Boeing to make planes from carbon fibre, a battle he won. Boeing's latest 787 Dreamliner planes are made from 50% carbon fibre and other composite materials, as opposed to the traditional 100% aluminium. They use 30% less fuel than their standard alternatives.

Manchester U team shows the influence of pre- and post-dispersion on the properties of GNP-enhanced epoxy

Researchers from The University of Manchester have conducted a study that presents a review of the three steps of manufacturing graphene/epoxy nano-composites. The possible pre-treatments of nanoparticles before dispersion are introduced, and their influence on the final nanocomposite properties discussed.

SEM images of fracture surface of aligned GNP based epoxy composite

SEM images of fracture surface of aligned GNP based epoxy composite

The study stresses interesting results, among which are improvements in various characteristics via the use of GNPs. For instance, an improvement of the thermal diffusivity of 220% was seen when compared to a non-oriented GNP epoxy sample. The work demonstrates how the addition of functionalized graphene platelets to an epoxy resin will allow it to act as electrical and thermal conductor rather than as insulator. The mechanical properties of functionalized GNP/epoxy composites show improvement of the interfacial bond.

Directa Plus announces graphene-enhanced eyewear collection by Ray-Ban collection with G+ inside

Directa Plus, a producer and supplier of graphene-based products for use in consumer and industrial markets, recently announced that its graphene-based materials have been selected by Luxottica Group, a company that designs, manufactures and sells eyewear, to enhance a new range of Ray-Ban glasses.

Ray-Ban updates that during the creation process of this collection, every detailâfrom design to production techniquesâhas been studied to make the best use of the characteristics of graphene. The molds, for example, were designed with special care to facilitate equal distribution of the material, a special mixture of resins and graphene, all over the front of the frame.

Pagination

- Previous page

- Page 32

- Next page