Graphene composites: introduction and market status - Page 9

Graphmatech and Steelhead Composites to develop graphene-enhanced hydrogen storage tanks

Graphmatech and Steelhead Composites have announced a collaboration on the development and production of a new high performance type IV pressure vessel liner. Expected improvements include reduced hydrogen leakage and increased resistance to extreme thermal and pressure conditions.

The partnership will combine Steelhead Composites’ leading pressure vessel technology, services, and market position with Graphmatech’s graphene-polymer composites for the hydrogen economy.

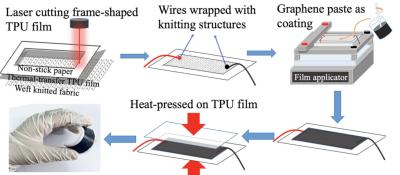

Researchers design graphene-based TPU/textile composite sensor that is flexible, durable, UV resistant, and electrically conductive

Researchers from the UK's Imperial College London have developed graphene-based flexible clothing sensors that can detect body movement, with potential applications in injury rehabilitation, human-computer interaction systems, and athletic training.

The researchers produced a new type of graphene-based TPU/textile composite sensor using small-scale manufacturing techniques such as laser cutting, film coating, and thermal transfer.

MCR Safety launches graphene-enhanced work gloves

Personal protection equipment maker, MCR Safety, recently introduced CT1071, a new Cut Level ‘E’ safety glove made with graphene fibers. It offers a choice of different coatings designed for different tasks and working environments. CT1071 has a 15-gauge shell specifically designed to take advantage of the ultra-lightweight nature of the new fibers. It’s a Cut Level ‘E’ glove yet it’s reportedly 25% lighter than similar gloves offering the level of protection. It is also designed to be comfortable and easy to wear.

As this fiber isn’t blended with any glass or steel, the high-level cut protection is maintained throughout the life of the glove. No fiber breakage means high durability, high comfort and no irritation. The diaphanous Nitrile Micro-Foam coating enables enhanced grip, even in oily conditions.

Martinrea wins automotive industry award for graphene-enhanced brake lines

Martinrea International, a global automotive supplier of value-added lightweight structures and propulsion systems (that has a collaboration with NanoXplore), was named a 2022 Automotive News PACE Award winner at the awards ceremony on September 19.

Martinrea was recognized for its brake lines with GrapheneGuard, which is said to be the first use of graphene in an automotive brake line application. Martinrea recognized the potential of graphene and developed the revolutionary GrapheneGuard coating technology which incorporates graphene into nylon. The development of GrapheneGuard is a convergence of material science innovation and process engineering that brings to the automotive market a brake line coating that reportedly has unmatched properties. The material can provide up to 25 percent weight savings while simultaneously demonstrating superior strength, greater abrasion protection, and improved chemical resistance, all while utilizing current manufacturing equipment and processes.

Haydale supplies graphene to NeoEnpla for use in food packaging

Haydale has started to supply South Korean plastics developer NeoEnpla with functionalized graphene nano-platelets (GNPs) for use in food packaging. Functionalized using Haydale's patented HDPlas® technology, the GNP-enhanced thermoplastic has been used to manufacture an initial sample range of food storage zipper bags and biodegradable plastic bags.

LLDPE and LDPE (low density polyethylene) are widely used in food packaging and are ideal for food storage due to their high resistance to moisture, tearing and chemicals. The graphene-enhanced zipper bags have reportedly shown an increase in tensile strength of 31% compared to non-graphene LLDPE (linear low-density polyethylene) zipper bags. In addition, the increased mechanical strength of the graphene zipper bags allows light weighting of the plastic, reducing the film thickness from 90µm to 60µm per bag.

Mito Material Solutions opens new facility in Indianapolis

Mito Material Solutions has launched its new 7,000 sq ft headquarters in Indianapolis. The company develops additives to enhance performance of composites and plastics, including its flagship graphene oxide-based additive E-GO.

At the new facility, Mito houses its staff offices, commercial-scale graphene functionalization and dispersion equipment, an R&D laboratory where the company can fabricate sample parts with its materials and an in-house analytical room for testing material properties. The R&D lab includes capabilities for hand layup, vacuum infusion and waterjet cutting with more equipment to come, and the testing room includes equipment to test a sample part’s flexure and tensile strength, interlaminar toughness, compression strength, as well as thermal, electrical and vibrational properties.

Graphene aerospace balloons to promote Malaysia's rubber industry

The Malaysian Rubber Council (MRC) has high hopes for its new aerospace balloon, made of a combination of graphene extract and natural rubber. The MRC's CEO, Nor Hizwan Ahmad, said the research and collaboration carried out by Meditech Gloves Sdn Bhd and Cranfield University in the United Kingdom has shown huge potential through the application of this product and findings.

The MRC CEO said the evolution from plantation to the aerospace industry is a great achievement for Malaysia’s rubber industry. He also said the aerospace balloon made of graphene extract and infused into natural rubber is new in the market and patented by Levidian Nanosystems.

Researchers use green chemistry approach to synthesize graphene oxide/silver nanocomposites

Researchers from Pakistan have reported a green approach to the synthesis of graphene oxide/silver nanoparticle nanocomposite.

Metallic nanoparticles (NPs) have various benefits in the field of electrochemistry. Because of their small size, nanoparticles may enhance the contact area of the electrode in use. Furthermore, metallic nanoparticles may boost the rate of mass transfer and provide quick electron transference, increasing the sensitivities of the used electrodes. Silver nanoparticles (AgNPs) are relatively low cost and have distinct physical and chemical characteristics that make them helpful in several optical, chemical, and catalytic functions. Nanoscale composites of metallic nanoparticles and graphene oxide have promising applications in energy storage, supercapacitors, and electronics.

Levidian and Adamant to collaborate on development of graphene-enhanced composite materials

Levidian Nanosystems and Adamant Composites Limited have signed a joint development agreement (JDA) to collaborate on enhancing composite materials with Levidian’s unique graphene.

Over the next three years, the two companies will work together to incorporate Levidian’s sustainable graphene in a range of composite materials. Levidian uses plasma chemistry to crack methane into hydrogen and graphene. This process means their graphene has no batch-to-batch variation, a very small number of layers, and a positive environmental impact. The addition of graphene to composite materials and components will lead to improved process times while augmenting physical properties.

Researchers develop new process for low-cost graphene production

A team of researchers from the Institute for Plasmas and Nuclear Fusion (IPFN), Instituto Superior Técnico, have reported a new process to fabricate free-standing graphene using plasma technology, at much lower production cost than the other existing market solutions.

The invention was granted the first international patent on the Process, reactor and system for fabrication of free-standing two-dimensional nanostructures using plasma technology (ref. US 11254575B2), by the US Patent Office.

Pagination

- Previous page

- Page 9

- Next page