Graphene CVD sheets - updates and market status - Page 10

MIT team uses graphene to create ultra-strong 3D materials

Researchers at MIT have designed a strong and lightweight material, by compressing and fusing flakes of graphene. The new material, a sponge-like configuration with a density of just 5%, can have a strength 10 times that of steel. This work could pose an interesting way of transforming graphene into useful 3D objects and items.

The team developed the product by using a combination of both heat and pressure, compressing and fusing the flakes of graphene together. This process produced a strong, stable structure whose form resembles that of some corals and microscopic creatures called diatoms. These shapes, which have an enormous surface area in proportion to their volume, proved to be remarkably strong.

EU's Gladiator project demonstrates a large 2 x 1 cm flexible OLED panel with graphene electrodes

The Fraunhofer Institute FEP and other partners at EU GLADIATOR project developed a functional flexible OLED lighting device based on graphene electrodes. This device is 2 x 1 cm in size - much larger the previous prototype developed as part of that project last year.

The graphene electrodes were produced in a CVD-based process. The graphene was deposited on a copper film, covered with a flexible polymer carrier and then the copper was etched away.

CealTech to offer pre-booking and sales in late January

CealTech recently announced its new laboratories and facilities, and the Norway-based pure PE-CVD graphene producer will begin graphene production in March 2017. CealTech now announced that it will offer pre-booking and sales in late January on its web site.

The company also released the promotion video you see below.

CealTech progresses to the next level with new large PE-CVD graphene production facility

Norway-based CealTech was established in 2012 to commercialize a patented 3D graphene production method. The company has now signed a contact to a new larger facility (located at Forus in Stavanger, Norway) as the company is entering the 2nd phase of its growth strategy.

CealTech will establish its own laboratories in the new facility in early 2017, as it aims to begin graphene production in March 2017, using the first FORZA graphene production unit and automated graphene packing line. CealTech aims to become the world's largest producer of pure PE-CVD graphene following the commission of the new production unit.

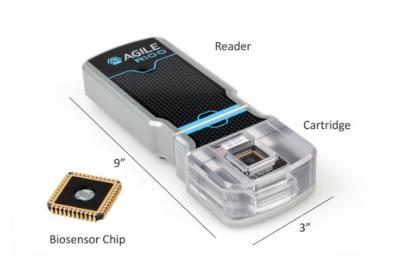

Nanomedical Diagnostics starts shipping its graphene-based sensors, explains its technology and business to Graphene-Info

San Diego-based Nanomedical Diagnostics, established in late 2013 to develop cutting-edge diagnostics equipment, recently started shipping its graphene-based sensors and the AGILE R100 system which allows for real-time detection of small molecules - with no lower size limit. Nanomedical's graphene-based sensors enable faster sample processing, greater accuracy, portability and cost savings.

The company's CEO, Ross Bundy, was kind enough to explain the company's technology and business to us.

A visit to the NPL and recent research updates

A few weeks ago we visited the National Physical Laboratory (NPL) in Teddington, UK. We were given a tour of the facilities, the graphene labs and met with several key researchers and the business development team. The NPL is the UK's national measurement institute, and is a world-leading measurement standards institute - and certainly one of the leading institutes in the field of graphene metrology.

The NPL's facilities are very impressive, it's a beautiful campus set in the lovely town of Teddington - about half an hour by train from central London. The research facilities and laboratories were very well equipped and we pleasantly surprised to find out how nice and hospitable the researchers were. It was great to see so many graphene related activities at the NPL.

Graphenea announces a new Easy Transfer graphene CVD transfer process

Graphenea launched a new graphene transfer procedure, which they call "Easy Transfer". The CVD graphene maker says this is the easiest way to transfer mono layer graphene onto any substrate. The Easy Transfer process avoids metal etching and any hazardous chemical handling, and the thin film manipulation is done at Graphenea's plant.

Easy Transfer is available in 1x1 cm and 1x1 inch sizes, and can be used to cut lead time and research work. Companies are welcome to send their substrates to Graphenea for coatings. The price for this process is $80 for 1x1cm and $120 for 1x1 inch.

Graphene coating may solve the glass corrosion problem

Researchers at the Center for Multidimensional Carbon Materials (CMCM) within the Institute for Basic Science (IBS), have demonstrated a graphene coating that protects glass from corrosion. Their research has been said to hold potential for solving problems related to glass corrosion in several industries.

The IBS scientists grew graphene on copper and transferred either one or two atom-thick layers of graphene onto both sides of rectangular pieces of glass. The effectiveness of the graphene coating was evaluated by water immersion testing and observing the differences between uncoated and coated glass. After 120 days of immersion in water at 60 C, uncoated glass samples had significantly increased in surface roughness and defects, and reduced in fracture strength. In contrast, both the single and double layer graphene-coated glasses had essentially no change in both fracture strength and surface roughness.

Graphenea updates on its CVD graphene status

Last month we asked several graphene experts about their thoughts on the commercial potential of CVD as a graphene production process. This interesting discussion led to my talk with Jesus de la Fuente, Graphenea's Founder & CEO.

Graphenea is one of the world's leaders in CVD graphene, and Jesus kindly agreed to update us on his thoughts on CVD and the recent advances made at Graphenea.

Aixtron takes part in “HEA2D” project to investigate the production, qualities, and applications of 2D nanomaterials

Aixtron, a leading provider of deposition equipment, is working together with five partners in the “HEA2D” project to investigate the production, qualities, and applications of 2D nanomaterials.

Aixtron, a leading provider of deposition equipment, is working together with five partners in the “HEA2D” project to investigate the production, qualities, and applications of 2D nanomaterials.

The joint project is now researching an end-to-end processing chain consisting of various deposition processes for 2D materials, processes for transfer onto plastic foils, and mass integration into plastics components. AIXTRON’s partners for implementing systems technology and integrating materials into plastic molded parts are the Fraunhofer Institute for Production Technology (IPT), Coatema Coating Machinery, and Kunststoff-Institut Lüdenscheid (K.I.M.W.). This work is being supported in terms of nano-analytics and the development of prototype components by the Institutes of “Electronic Materials and Nanostructures” (University of Duisburg-Essen) and “Graphene-based Nanotechnology” (University of Siegen).

Pagination

- Previous page

- Page 10

- Next page