Graphene Oxide: Introduction and Market News - Page 22

Zenyatta Ventures announced successful testing of its material in Si-G anodes for Li-ion batteries

Zenyatta Ventures has announced the successful testing of its graphene oxide material by a U.S. based advanced materials company developing silicon-graphene anodes for the next generation of lithium-ion batteries.

Zenyatta Ventures has announced the successful testing of its graphene oxide material by a U.S. based advanced materials company developing silicon-graphene anodes for the next generation of lithium-ion batteries.

Zenyatta stated that preliminary results showed the ease of processing with its graphene oxide and similar electrochemical performance compared to the control material that is currently being used by the U.S. company. Zenyatta's high-purity graphite was recently converted to graphene oxide and then sent to the U.S. collaborator for testing as an advanced nano-material in a new Lithium-ion battery.

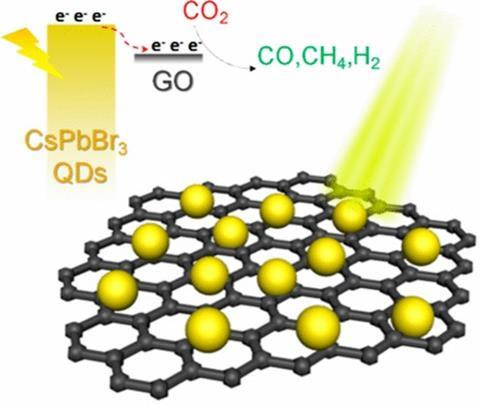

Graphene oxide combines with perovskite quantum dots to create artificial photosynthesis

Researchers from Sun Yat-Sen University in China have created a composite of graphene oxide and perovskite quantum dots that can reduce CO2 when stimulated with light. It is referred to as the first known example of artificial photosynthesis based on perovskite quantum dots and GO.

The team prepared quantum dots semiconductor nanoparticles of a highly stable cesiumlead halide perovskite, as well as a composite material made of these quantum dots and graphene oxide. Both materials showed an efficient absorption of visible light and strong luminescence. The team used these products to achieve a fundamental step in artificial photosynthesis the reduction of CO2. To simulate sunlight, they used a xenon lamp with an appropriate filter.

Non-flammable graphene oxide membrane developed for safe mass production

Researchers at the University of Arkansas have demonstrated a simple and scalable method for turning graphene oxide into a non-flammable and paper-like graphene membrane that can be used in large-scale production. This tackles the issue of high flammability, which has, according to the team, been an obstacle to further development and commercialization.

Using metal ions with three or more positive charges, the researchers bonded graphene-oxide flakes into a transparent membrane. This new form of material is flexible, nontoxic and mechanically strong, in addition to being non-flammable. Further testing of the material suggested that crosslinking, or bonding, using transition metals and rare-earth metals, caused the graphene oxide to possess new semiconducting, magnetic and optical properties.

Graphene may assist in producing cells vital for nerve regeneration

Researchers at Iowa State University (ISU) are developing a graphene-based method to transform stem cells into Schwann-like cells (cells of great importance for various nerve regeneration efforts). If successful, this process has potential to replace the complicated and expensive process used today.

The team's method uses inkjet printers to print multi-layer graphene circuits and also uses lasers to treat and improve the surface structure and conductivity of those circuits. It turns out that mesenchymal stem cells adhere and grow well on the treated circuit’s rough 3D nanostructures. With the addition of small doses of electricity 100 millivolts for 10 minutes per day over 15 days the stem cells become Schwann-like cells.

Graphene-Info launches the Graphene Catalog - your source for graphene materials!

We're proud to launch a new service - the Graphene Catalog, a revolutionary new graphene materials directory. This first-of-its-kind catalog lists graphene materials available on the market, divided into categories - graphene flakes (including reduced GO), graphene oxide, graphene sheets and 3D printing filaments.

So if you're looking for graphene materials, all you have to do is click here and get started. We can also help with finding a graphene developer to produce custom graphene materials. Contact us for more information.

Exeter team uses graphene oxide to design flexible and transparent memory devices

Researchers from the University of Exeter have developed an innovative new memory using a hybrid of graphene oxide and titanium oxide. These devices are reportedly low cost and environmentally friendly to produce, and are also suited for use in flexible electronic devices such as 'bendable' mobile phone, computer and television screens, and even 'intelligent' clothing. These devices may also have the potential to offer a cheaper and more adaptable alternative to 'flash memory', which is currently used in many common devices.

The team stated: "Using graphene oxide to produce memory devices has been reported before, but they were typically very large, slow, and aimed at the 'cheap and cheerful' end of the electronics goods market. Our hybrid graphene oxide-titanium oxide memory is, in contrast, just 50 nanometres long and 8 nanometres thick and can be written to and read from in less than five nanosecondsâwith one nanometre being one billionth of a metre and one nanosecond a billionth of a second."

Manchester U team makes headway in using GO membranes to turn saltwater into drinking water

Scientists at The University of Manchester have made a breakthrough in the field of graphene oxide membranes for water desalination. Previous research at The University of Manchester found that when immersed in water, graphene oxide membranes become slightly swollen and smaller salts flow through the membrane along with water, but larger ions or molecules are blocked. Now, the team has devised a strategy to avoid the swelling of the membrane when exposed to water. The pore size in the membrane can be precisely controlled which can sieve common salts out of salty water and make it safe to drink.

When the common salts are dissolved in water, they form a 'shell' of water molecules around the salt molecules. This allows the tiny capillaries of the graphene oxide membranes to block the salt from flowing along with the water. Water molecules are able to pass through the membrane barrier and flow anomalously fast which is ideal for application of these membranes for desalination.

3D printed bacteria could be used to reduce graphene oxide

Researchers at Delft University have shown that placing certain types of bacteria on flat sheets of graphene oxide can turn it into a reduced version of the compound (rGO) by pulling oxygen atoms off the material as they metabolize. This turns the popular process of GO reduction, normally done with chemicals or high heat, into a much cheaper, more environmentally friendly process.

While the traditional method of reducing graphene with heat or chemicals is still more effective, the bacterial method could be very useful in the production of precise, small-scale graphene structures such as those produced with a 3D printer. In this work, the researchers document how they modified a $300 CoLiDo 3D printer by replacing the extruder with a pipet tip and tubing system. This alteration allows the liquid biological ink (‘bioink’) to be transported under ambient temperatures that are amenable to microbes, rather than the elevated temperatures that are applied to melt plastic filament, the team explains.

A new graphene oxide coating to improve the performance of lithium-sulfur batteries

Researchers at Yale University have developed an ultra-thin coating material, based on graphene oxide, that has the potential to extend the life and improve the efficiency of lithium-sulfur batteries. The newly developed material is a dendrimer-graphene oxide composite film, that can be applied to any sulfur cathode.

The researchers state that sulfur cathodes coated with the material can be stably discharged and recharged for more than 1,000 cycles, enhancing the battery’s efficiency and number of cycles. In addition, they said the developed film is so thin and light it will not affect the overall size or weight of the battery, and thus it will function without compromising the energy and power density of the device.

Rutgers licenses microwave-based graphene production method to Everpower

Rutgers University has licensed a technology that allows for the mass production of high-quality graphene at a reduced cost to Everpower International Holdings, a New York-based investment company engaged in investing in emerging technologies and their integration into China, that has recently announced a collaboration agreement with Haydale.

The method uses microwaves to produce high-quality graphene from graphene oxide, and has the potential to generate large quantities of it at low cost. The ability to manufacture graphene on a large scale will allow Everpower to test a variety of products containing the material.

Pagination

- Previous page

- Page 22

- Next page