Graphene sensors: introduction and market status - Page 19

New graphene biosensor can detect SARS-CoV-2 in under a minute

Korean researchers have developed a graphene-based field-effect transistor-based biosensor that detects SARS-CoV-2 in nasopharyngeal swabs from patients with COVID-19, in less than one minute.

Currently, most diagnostic tests for COVID-19 rely on a technique called real-time reverse transcription-polymerase chain reaction (RT-PCR), which amplifies SARS-CoV-2 RNA from patient swabs so that tiny amounts of the virus can be detected. However, the method takes at least 3 hours, including a step to prepare the viral RNA for analysis. Edmond Changkyun Park, Seung Il Kim and colleagues wanted to develop a faster diagnostic test that could analyze patient samples directly from a tube of buffer containing the swabs, without any sample preparation steps.

Graphene to enable tiny self-powered temperature sensors

A team of researchers from the University of Oxford, Delft University and IBM Zurich has demonstrated that graphene can be used to build sensitive and self-powering temperature sensors. The findings could pave the way for the design of highly sensitive thermocouples, which could be integrated in nanodevices and even living cells.

On-chip temperature sensors that are scalable, reliable and installable into nanodevices are essential for future thermal management in CPUs. By determining the local heating in certain segments of a CPU through the distribution of temperature monitors along critical points, feedback can be provided to a control system. In response, thermal management could allow for the redistribution of the thermal load through spot cooling or load distribution, for instance among different computing cores, avoiding hot spots and enabling a longer device lifetime as well as saving energy. Such temperature sensors should have a small footprint, high accuracy, consume a minimum amount of power and be compatible with established nanofabrication techniques.

Graphene teams up with black phosphorus and black arsenic to create next-gen detectors

MIPT scientists and their colleagues from Japan and the U.S. have calculated the parameters of photodetectors made of layers of graphene and a combination of black phosphorus and black arsenic.

These sensors are able to detect radiation with energy less than the band gap of the constituent layers without graphene. It is also easy to modify them in order to increase their sensitivity to the required wavelength of light. Such sensors could replace any far-infrared and terahertz radiation detectors.

Lasers enable graphene-on-kevlar textiles for smart protective clothing

Researchers at Tsinghua University have used lasers to make graphene on Kevlar textiles, creating protective clothing that can record the wearer’s electrocardiogram (ECG) or sense a toxic gas.

Prototype of an intelligent protective vest based on the Kevlar-laser induced graphene textile (left) with a gas sensor and battery embedded in a design on the vest (top right) also shown in false color (bottom right). Credit: ACS Nano

Prototype of an intelligent protective vest based on the Kevlar-laser induced graphene textile (left) with a gas sensor and battery embedded in a design on the vest (top right) also shown in false color (bottom right). Credit: ACS Nano

Yingying Zhang and colleagues at Tsinghua University used a carbon dioxide laser to write on Kevlar, a synthetic polyamide fiber generally used to make body armor and personal protective clothing. The laser burned and depolymerized the Kevlar fibers and the carbon atoms recombined to form graphene, as shown by Raman spectroscopy. Using a motorized setup for the laser, they were able to scribe any design on the textile in minutes.

A new experimental pilot line will integrate graphene and related layered materials (GRMs) in semiconductor platforms

​The European Commission recently invited a group of Graphene Flagship partners and associated members to set up an experimental pilot line to integrate graphene and related layered materials (GRMs) in semiconductor platforms.

The project aims to establish a European ecosystem covering the entire value chain, from tool manufacturers and chemical and material providers to pilot lines. This collaborative project will pioneer the manufacture of new prototype electronics, photonics and sensors integrating GRMs. The 2D Experimental Pilot Line (2D-EPL) will offer prototyping services to companies, research centers and academics to develop their innovative technologies based on 2D materials in an established processing platform.

Sussex team granted £1 million funding to develop graphene-based applications like camouflage technology, smart tires and more

A University of Sussex research team, led by Professor Alan Dalton, has received new funding of £1 million from private company Advanced Material Development, to pursue their research into graphene and other nanomaterials.

The team will conduct research into various avenues, including camouflage technology to stop soldiers from being spotted by thermal imaging cameras or night vision goggles. The team will also develop their research into anti-counterfeiting graphene inks which can be printed onto clothes and medicine containers; incorporated into smart tires which monitor for problems; used on banknotes; included on metal-free radio-frequency identification tags (RFID) tags for supermarkets to track products; and wearable technology, including monitors for babies’ heartbeats or diabetic patients’ glucose levels.

Crumpled graphene could enable fast, simple and sensitive biosensors

Researchers at the University of Illinois at Urbana-Champaign have found that crumpling graphene makes it more than ten thousand times more sensitive to DNA by creating electrical "hot spots". This discovery could assist in addressing a known issue of graphene-based biosensors - the face that they require a lot of DNA in order to function properly.

"This sensor can detect ultra-low concentrations of molecules that are markers of disease, which is important for early diagnosis," said study leader Rashid Bashir, a professor of bioengineering and the dean of the Grainger College of Engineering at Illinois. "It's very sensitive, it's low-cost, it's easy to use, and it's using graphene in a new way."

How can graphene assist in the war on Coronavirus?

As researchers and companies all over the world set out to battle the Coronavirus pandemic, many are revisiting graphene as a material with potential for helping to win this fight. The reasons for such potential could be found in graphene's known antibacterial/antiviral properties, its beneficial traits for medical sensors and devices and more.

Graphene has been shown in the past as extremely useful for creating various sensors. Earlier this month, a team led by Boston College researchers used a sheet of graphene to track the electronic signals inherent in biological structures, in order to develop a platform to selectively identify deadly strains of bacteria. In October 2019, Rice University team under chemist James Tour transformed their laser-induced graphene (LIG) into self-sterilizing filters that grab pathogens out of the air and kill them with small pulses of electricity. Commercially sold graphene-based sensors exist, like the graphene oxide (GO) sensor developed by the ICN2 Nanobioelectronics and Biosensors group that was added in 2016 to the list products offered by Biolin Scientific, a prestigious instrumentation company devoted to the production of analytical devices. The Q-Sense GO sensor enables interaction studies of GO with various analytes (measured substances) of interest and may open the door to various applications with interest for diagnostics, safety/security and environmental monitoring.

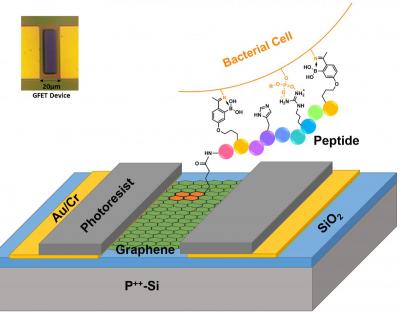

Graphene-based platform could selectively identify deadly strains of bacteria

A team led by Boston College researchers has used a sheet of graphene to track the electronic signals inherent in biological structures, in order to develop a platform to selectively identify deadly strains of bacteria. This effort could lead to more accurate targeting of infections with appropriate antibiotics, according to the team.

The prototype demonstrates the first selective, rapid, and inexpensive electrical detection of the pathogenic bacterial species Staphylococcus aureus and antibiotic resistant Acinetobacter baumannii on a single platform, said Boston College Professor of Physics Kenneth Burch, a lead co-author of the paper.

The UK establishes a Graphene Innovation Group, explains how graphene assists business goals

Following a Global Business innovation Programme initiated in 2019, and a collaborative visit to the US, the UK established a new Graphene Innovation Group (UK-GIG) that puts together 15 specialists from UK companies that together share many years of experience in graphene and expertise across the entire value chain.

Scott Storey, a Business Innovation Advisor at Inventya and the lead coordinator at the UK-GIG, explains more about the group - "We can take an everyday industrial challenge, apply our combined graphene knowledge, engineer and manufacture an effective solution, and take that solution to national and international markets. UK-GIG is now an established cohort of 15 UK-based graphene companies, ranging from early stage through to established businesses. The UK-GIG companies are fully aware of the huge potential for graphene technology to improve materials or be used in novel ways across multiple sectors. They are seeking collaboration opportunities where they can combine their expertise to do what they do best - solve problems, design graphene applications, and help commercialize an increasingly exciting field. They aim to make the UK the best place on earth to be grafting in graphene!"

We have reached out to some of the GIG members, to find out how has graphene effected their business and products, and the effects of graphene on their materials or devices.

Pagination

- Previous page

- Page 19

- Next page