Graphene sensors: introduction and market status - Page 25

Garmor creates extra strong polymeric coatings and innovative conductive fibers

Garmor, manufacturer of low-cost graphene oxide, rGO and developer of innovative GO production methods, recently developed a graphene-enhanced polymeric coating with a 390% reported improvement in tensile strength. Garmor stated that it is already marketing this technology as it has already been fielded and used in commercial applications. Here's a video showing side-by-side testing of the original polymer (left) and the graphene-enhanced polymer (right) shown at 4X normal speed.

In addition, Garmor announced the development of an innovative process for converting insulating polymeric fibers into electrically conductive fibers with minimal cost and no waste products. The method has resulted in composites with single-digit graphene loadings delivering conductivity as high as .023 S/cm. Garmor sees such performance as ideal for wearable sensors and other applications that require integrated approaches to solving weight and measurement issues.

Researchers design novel graphene-based terahertz detector

A team of researchers from Russia, UK, Japan and Italy has created a graphene-based terahertz detector.

The team explains that the reason for the inefficiency of existing terahertz detectors is the mismatch between the size of the detecting element, the transistorâabout one-millionth of a meterâand the typical wavelength of terahertz radiation, which is about 100 times greater. This results in the wave passing the detector by without any interaction.

Graphene electronics: commercialisation outlook for 2019

This is a guest post by Guillaume Chansin

Graphene is probably the most hyped material of the past decade, but so far commercial applications have been limited. Graphene is mostly used as an additive inside composites and plastics to enhance their thermal or structural properties. In the most recent high profile case, Huawei announced the integration of a passive graphene cooling film to improve heat management inside one of their smartphones. While this is a useful use of graphene, it is a far cry from the disruptive electronics that were promised when the material was first isolated.

It is worth considering that both investments and patent filings in graphene peaked in 2015. Nearly four years later, we can expect to see some of these to start paying off with some product launches.

Pristine graphene could lead to improved solar cells and photodetectors

An international research team, co-led by researchers at the University of California, Riverside, which also included researchers at MIT, Nanyang Technological University, Singapore; Institute of High Performance Computing, Singapore; UC Berkeley; and National Institute for Materials Science, Japan, has found a new mechanism for highly-efficient charge and energy flow in graphene, opening the door to new types of light-harvesting devices.

The researchers made pristine graphene into different geometric shapes, connecting narrow ribbons and crosses to wide open rectangular regions. They found that when light illuminated constricted areas, such as the region where a narrow ribbon connected two wide regions, a large light-induced current, or photocurrent, was detected.

Haydale to work with Wheelsure on graphene sensor project

Haydale Graphene Industries is to partner with Wheelsure Holdings to work on a graphene pressure sensor. The project will begin in January and will involve production of a smart graphene pressure sensor targeting the fastener market.

Haydale Graphene Industries is to partner with Wheelsure Holdings to work on a graphene pressure sensor. The project will begin in January and will involve production of a smart graphene pressure sensor targeting the fastener market.

The sensor will integrate Haydale's graphene sensor technology and safety product developer Wheelsure's failsafe locking device. Both parties entered into a commission-based sales arrangement , under which Haydale will introduce the product to customers.

NYU team's findings on defects in graphene to benefit environmental and medical sensors

A team of NYU researchers has tackled the longstanding question of how to build ultra-sensitive, ultra-small electrochemical sensors with homogeneous and predictable properties, by discovering how to engineer graphene structure on an atomic level. The team's findings could benefit biochemical detection, environmental monitoring, and lab-on-a-chip applications

Finely tuned electrochemical sensors (also referred to as electrodes) that are as small as biological cells have tremendous potential for medical diagnostics and environmental monitoring systems. However, efforts to develop them have encountered obstacles, like the lack of quantitative principles to guide the precise engineering of the electrode sensitivity to biochemical molecules.

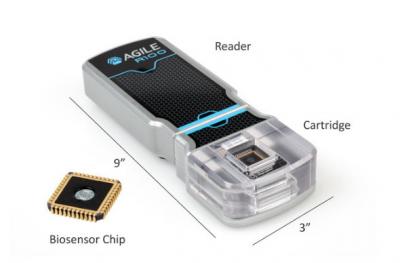

Nanomedical Diagnostics reporting major growth

Nanomedical Diagnostics, a U.S-based producer of graphene biosensors for pharmaceutical and biotherapeutics research, has announced a headquarters relocation, effectively tripling its space from 5,200 to 16,500 square feet.

This past year has seen exponential growth, both domestically and internationally, for the sales of our drug discovery platforms. We’re in the great position of having to move to a new space to accommodate expanded production and R&D, says Nanomedical Diagnostics CEO, Ross Bundy. Our new building enables better operational efficiencies for our production lines and brings departments that were formerly separated in different locations together under one roof. This allows for better collaboration and innovation as we launch new products and grow our staff.

GRAPHOSITE project aims to develop an efficient composite monitoring tool

GRAPHOSITE is a 30-month project which started on the 1st August 2018. Its main objective is to develop a Graphene Sensor for Defect Detection and Predictive Maintenance in Composite Materials, for use as a highly efficient, more convenient composite monitoring tool.

This project has been supported by the Innovate UK (£1.3 Million Grant-Project Ref. 104266) and has the participation of 6 Partners: Advise-Deta (project coordinator), DZP Technologies, Cambridge Nanomaterials Technology, Haydale Composite Solutions and TWI.

Versarien signs MOU with China Railway

Versarien has announced that it has signed a Memorandum of Understanding ("MOU") with China Tiesiju Civil Engineering Group Co Ltd. ("CTCE"), a subsidiary of China Railway Group Limited ("CRG").

Versarien has announced that it has signed a Memorandum of Understanding ("MOU") with China Tiesiju Civil Engineering Group Co Ltd. ("CTCE"), a subsidiary of China Railway Group Limited ("CRG").

CRG is one of the world's largest construction and engineering contractors and is listed on the Shanghai and Hong Kong Stock Exchanges. CTCE is specifically focused on railway, bridge, tunnel and highway infrastructure engineering. It is active in China and overseas, including in Asia, Africa, Latin America and the Middle East.

Graphene to enable ALS diagnosis

A team of researchers from the University of Illinois at Chicago has been working on a way to facilitate ALS diagnosis by using a thin sheet of graphene. This material produces constant vibrations, also known as phonons, whose characteristics change once other materials are placed on its surface. By measuring these changes, researchers are able to tell the differences in the composition of different materials.

Graphene is just one atom thick, so a molecule on its surface in comparison is enormous and can produce a specific change in graphene’s phonon energy, which we can measure, Vikas Berry, associate professor and head of chemical engineering in the UIC College of Engineering and an author of the paper, said in a news release.

Pagination

- Previous page

- Page 25

- Next page