Graphene sensors: introduction and market status - Page 37

Fractal 'snowflake' design to improve graphene photodetectors

Researchers from Purdue University in the U.S have shown that a snowflake-like fractal design (in which the same pattern repeats at smaller and smaller scales) can increase graphene's inherently low optical absorption. This could lead to graphene photodetectors with an order-of-magnitude increase in photovoltage, along with ultrafast light detection and other advantages.

Graphene has an intrinsically low optical absorption, which is a major drawback for use in photodetectors. To address this issue, the Purdue researchers designed a graphene photodetector with gold contacts in the form of a snowflake-like fractal metasurface. They demonstrated that the fractal pattern does a better job of collecting photons across a wide range of frequencies compared to a plain gold-graphene edge, enabling the new design to generate 10 times more photovoltage.

Graphene and porphyrins join to create an exciting new material

Researchers at the Technical University of Munich have found that graphene can be combined with porphyrins, the molecules that convey oxygen in haemoglobin and absorb light during photosynthesis, to get a material with exciting new properties. The resulting hybrid structures could be used in the field of molecular electronics, solar cells and in developing new sensors.

The technique involves growing a graphene layer on a surface of silver to use its catalytic properties. Then, under ultra-high vacuum conditions, porphyrin molecules are added. These lose the hydrogen atoms from their periphery when heated on the metal surface, and they end up connecting to the graphene edges.

Polish team creates transparent cryogenic temperature sensor

Researchers from the Lodz University of Technology in Poland have designed a transparent, flexible cryogenic temperature sensor with graphene structures as sensing elements. Such sensors could be useful for any field that requires operating in low-temperatures, such as medical diagnostics, space exploration and aviation, processing and storage of food and scientific research.

The sensors were repeatedly cooled from room temperature to cryogenic temperature. Graphene structures were characterized using Raman spectroscopy. The observation of the resistance changes as a function of temperature indicates the potential use of graphene in the construction of temperature sensors. The temperature characteristics of the analyzed graphene sensors exhibit no clear anomalies or strong non-linearity in the entire studied temperature range (as compared to the typical carbon sensor).

Looking back into the hottest graphene topics in 2015 - getting ready to summarize 2016

2016 will soon come to an end, and we are getting ready to summarize this exciting year in the graphene industry. One year ago we posted the top top graphene stories in 2015, and you can see the list below again. Interestingly, the most popular stories in 2015 were about graphene's potential for energy storage - mainly supercapacitors and batteries.

- Sunvault Energy and Edison Power present a 10,000 Farad graphene supercapacitor

- Sunvault's graphene-based supercapacitor declared to someday replace Lithium-ion batteries and compete with Tesla's battery aspirations

- Stanford scientists make graphene-aluminum battery that charges quickly and lasts over 7,000 cycles

- Graphene 3D Lab starts selling conductive graphene filament for 3D printing

- Will Tesla's Roadster 3.0 use a graphene-enhanced battery?

- Berkeley scientists design graphene-based loudspeakers and microphones

- World's first commercial graphene-based supercapacitor chosen for use in spacecraft

- IDTechEx's analyst explains his views on the graphene market

- Scientists design a large-scale roll-to-roll graphene manufacturing process

- Graphene-enhanced guitar shown at Graphene Live!

Below you can see 2015's top 10 graphene applications, ranked by the number of posts written about them. Back then we were a bit surprised to see graphene sensors at #2 - but recently companies have actually started to commercialize graphene sensors (see here and here) and this is a very promising field.

UCF researchers receive $1.3 million from DARPA to develop a graphene-enhanced IR detector

The Defense Advanced Research Projects Agency (DARPA) has reportedly awarded a $1.3 million grant to a team from the University of Central Florida (UCF) to fund the development of a graphene-enhanced next-generation infrared detector that could be used in fields like night vision, meteorology, and space exploration.

The UCF team is working on an entirely new type of detector that relies on graphene. The researchers plan to use graphene to make an infrared detector that is small, portable, doesn't need to be cooled, and produces high-resolution images. Unlike current technologies, which can detect only one band of light, the next-gen detector would be tunable and able to see a range of bands.

Exeter team unveils novel graphene production method that could accelerate commercial graphene use

Researchers from the University of Exeter have developed a new method for creating entire device arrays directly on the copper substrates used for commercial manufacture of graphene. Complete and fully-functional devices can then be transferred to a substrate of choice, such as silicon, plastics or even textiles.

This new approach is said to be cheaper, simpler and less time consuming than conventional ways of producing graphene-based devices, thus holding real potential to open up the use of cheap-to-produce graphene devices for a host of applications from gas and biomedical sensors to displays.

Graphene "silly putty" enables next-gen sensors

Researchers in AMBER, the materials science research center located in Trinity College Dublin and funded by Science Foundation Ireland, have used graphene-enhanced "silly putty" (polysilicone) to create extremely sensitive sensors. This fascinating research offers exciting possibilities for applications in new, inexpensive devices and diagnostics in medicine and other sectors.

The researchers discovered that the electrical resistance of putty infused with graphene (G-putty) was extremely sensitive to the slightest deformation or impact. They mounted the G-putty onto the chest and neck of human subjects and used it to measure breathing, pulse and even blood pressure. It showed unprecedented sensitivity as a sensor for strain and pressure, being hundreds of times more sensitive than normal sensors. The G-putty also works as a very sensitive impact sensor, able to detect the footsteps of small spiders. The scientists believe that this material will find applications in a range of medical devices.

Novel graphene nano-calligraphy method holds potential for improved sensors

Scientists at The University of Manchester in the UK and Karlsruhe Institute of Technology (KIT) in Germany have designed a method to chemically modify small regions of graphene with high precision, leading to extreme miniaturization of chemical and biological sensors which can be used in blood tests, minimizing the amount of blood a patient is required to give.

The team has shown that it is possible to combine graphene with chemical and biological molecules and form patterns. Using technology that resembles writing with a fountain pen, the scientists were able to deliver chemical droplets to the surface of graphene in very small volumes. In order to achieve extremely fine chemical patterns, the researchers used droplets of chemicals less than 100 attolitres (10-16 L) in volume - that’s 1/10,000,000,000,000,000th of a liter!

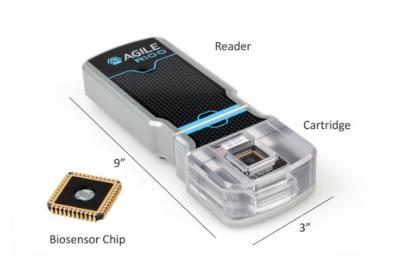

Nanomedical Diagnostics starts shipping its graphene-based sensors, explains its technology and business to Graphene-Info

San Diego-based Nanomedical Diagnostics, established in late 2013 to develop cutting-edge diagnostics equipment, recently started shipping its graphene-based sensors and the AGILE R100 system which allows for real-time detection of small molecules - with no lower size limit. Nanomedical's graphene-based sensors enable faster sample processing, greater accuracy, portability and cost savings.

The company's CEO, Ross Bundy, was kind enough to explain the company's technology and business to us.

Biolin Scientific commercializes a graphene oxide sensor developed by ICN2

A graphene oxide (GO) sensor co-developed by the ICN2 Nanobioelectronics and Biosensors group has recently been added to the list products offered by Biolin Scientific, a prestigious instrumentation company devoted to the production of analytical devices. The Q-Sense GO sensor enables interaction studies of GO with various analytes (measured substances) of interest and may open the door to various applications with interest for diagnostics, safety/security and environmental monitoring.

Biolin Scientific, a leading Nordic instrumentation company, develops products based on nanotechnology and advanced measurement techniques. The company has a line of instrumentation called Q-Sense, which deals with instruments that enable real-time analysis of surface-molecule interactions with nanogram precision for a wide variety of samples and measurement conditions. Biolin Scientific wanted to incorporate a graphene coated sensor in its Q-Sense sensors list. The collaboration between ICN2 and the Nordic company became plausible because the Institute already had expertise transferring graphene to the surface of interest.

Pagination

- Previous page

- Page 37

- Next page