Graphene sensors: introduction and market status - Page 50

Flexible transparent graphene electrodes may enable electronic tattoos

Researchesr from Korea's Ulsan, KAIST and ETRI institutes developed a process that produces flexible transparent graphene electrodes that can be attached to the skin (or any kind of delicate object). This could enable applications such as electronic tattoo-like stickers or bio-signal sensors.

A graphene metal fiber composite ise used, which lowers the resistance of the transparent electrode to approximately 1/20th of existing ones. This enables the electrodes to be used in flexible displays or sensors. The new process is similar to a widely-used semiconductor process which means that this can be scaled commercially.

Graphenea opens US branch, establishes an application laboratory

Graphenea has opened a branch in the USA to assist more immediate service of the company's North American customers. The US branch, Graphenea Inc, is based in Cambridge (Boston), MA, due to the close relation that the company has with research giants Massachusetts Institute of Technology (MIT) and Harvard. Apart from developing collaborative projects with those two partners, and acting as a sales outpost for its renown high-quality graphene, Graphenea Inc will set up an Applications Laboratory to help develop custom graphene materials.

The US outpost of Graphenea will continue and enhance the research excellence of the company, with planned hirings of full time R&D and Business Development personnel, says Jesus de la Fuente, CEO of Graphenea. The most pronounced application directions that we will pursue will be advanced polymers, thermal interface materials, energy storage, and (bio)sensors.

Graphene quantum dots enables a multi functional bio-sensor

Researchers from from Zhejiang Normal University in China developed a biocompatible bio-sensor that can simultaneous detection multiple biomarkers, such as DNA and proteins. Those sensors are made from carbon materials - mainly graphene-oxide (GO) and graphene quantum dots (GQDs).

The researchers explain hat GQDs rae promising environmentally friendly and biocompatible nanomaterials that can be used to design new fluorescence detection platforms in vitro and in vivo. The researchers use the specifically designed fluorescence on-off-on process that takes advantage of the intense and dual-color fluorescence of the GQDs, in addition to the efficient quenching effect of GO. The high emission efficiency of GQDs guarantees the high sensitivity of the constructed biosensors, while the good biocompatibility is promising for use of biosensors in vivo.

Graphene mixed with a plant creates a bio-inert superparamagnetic material

Researchers from India developed a new superparamagnetic hybrid material made from graphene and the amaranthus dubius plant. This plant is used for food (it's high on protein and contains several vitamins and minerals). Superparamagnetic materials can be used to make very sensitive and accurate sensors.

This new material is biologically inert (as both graphene and the plant are inert) and so this may be useful for applications in biology (such as bio-sensors).

Graphene enables the ideal chemical sensor

Researchers from the University of Illinois at Chicago (UIC) developed a graphene-based highly sensitive chemical sensor (an electronic "nose" if you will). The graphene enabled the researchers to increase the sensitivity to absorbed gas molecules by 300 times compared to current technology.

Interestingly, the graphene's grain boundaries are key to this achievement. The researchers discovered that the gas molecules are attracted to these grain boundaries, and so this is the ideal spot for the detection of these molecules. They explain that the irregular nature of the grain boundary produces hundreds of electron-transport gaps with different sensitivities - as if there are multiple switches all working in parallel.

Ultra sensitive bio-sensor developed from patterned graphene

Researchers from the University of Swansea developed an ultra-sensitive biosensor based on graphene. According to the researchers, this sensor is more than five times more sensitive than bioassay tests currently in use.

The sensor is based on large-area graphene devices grown on silicon carbide. The graphene was later patterned and then attached to bioreceptor molecules. These molecules act as receptors and they bind to the target molecule.

Graphene Frontiers partners with CNSE on a $5 million graphene fabrication project

In July 2014, Graphene Frontier launched the "six sensors" brand for highly-sensitive chemical and biological GFET-based sensors following a financing round of $1.6 million. Graphene Frontiers announced a partnership with the Colleges of Nanoscale Science and Engineering (CNSE) at SUNY Polytechnic Institute (SUNY Poly) to develop next generation graphene-based processes, technologies, and techniques.

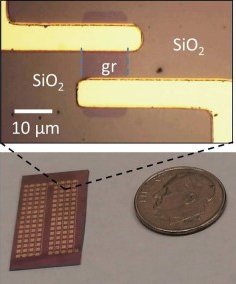

Graphene Frontiers G-FET sensor

Graphene Frontiers G-FET sensor

As part of the partnership, Graphene Frontiers and the CNSE will build a 300 mm fabrication process and wafer-transfer facility. The total investment in this project will reach $5 million over 3 years (and will be funded by the CNSE and Graphene Frontiers) and the project will employ 27 employees.

Graphene-based multi-modal bio-sensor

Researchers from the University of Pennsylvania demonstrated a graphene-based mutli-modal bio-sensor that can transmit transducing protein binding events into optical, electrical, and mechanical signals.

Such a multi-modal sensor means that you can inspect a single sample and obtain information from the three properties (optical, electrical and mechanical). This could lead to a sensor that outperforms single-mode sensors even if each signal detection by itself is not the best one. The researchers say that their sensor achieves a 100-times improvement in the sensing dynamic range over current single-mode sensors.

Plastic Logic and the CGC demonstrate the first graphene-based flexible display

In June 2013, Cambridge University's Graphene Centre (CGC) and Plastic Logic started to develop a transparent graphene-based backplane for flexible displays. Now Plastic Logic demonstrated the first display that was developed in that collaboration research. Plastic Logic says that this is the first time graphene has been used in a transistor-based flexible device.

The prototype (shown above) is an active-matrix electrophoretic (E Ink) display fabricated on flexible plastic. The electrodes are made from solution-processed graphene which was patterned after deposition with micron-scale features. The prototype has a pixel density of 150 PPI and was made at low temperatures (less than 100 degrees celsius). This is just a prototype of course and you can see many defects in display.

Wearable sensors developed from graphene-coated rubber bands

Researchers from Trinity College in Ireland developed wearable sensors by coating simple rubber bands with graphene. The idea is that the rubber band changes its electric conductivity when it stretches - so even tiny movements (such as breathing or pulse) can be sensed. Such sensors can also be used in the automotive industry, robotics, medical devices and more.

The researchers say that their method is simple and compatible with normal manufacturing techniques. The basic material (rubber) is very cheap of course.

Pagination

- Previous page

- Page 50

- Next page