Graphene-Enhanced Composite Materials Improve Lightning-Strike Performance

The following is a sponsored post by Haydale

The following is a sponsored post by Haydale

Haydale Composite Solutions are pleased to announce the production of graphene-enhanced electrically-conductive carbon fibre-reinforced composite materials with improved resistance to damage from a severe lightning-strike event.

Carbon fibre-reinforced composite materials, as used in many aerospace structures and components, are vulnerable to damage from lightning strikes. However, the addition of functionalised nano materials to the epoxy resin through the use of Haydale’s patented plasma functionalisation process, HDPlas, has been demonstrated to significantly improve the electrical conductivity of the epoxy resin which allows the laminate to dissipate the energy of the lightning strike throughout the structure thereby reducing the localised heating which causes damage in a lightning-strike event. Importantly, these improvements have been achieved without any major issues with existing manufacturing processes.

Haydale secures £3.26 million investment and plans to enter the Chinese market

UK-based Haydale has announced a collaboration agreement with Everpower International Holdings, a New York-based investment company engaged in investing in emerging technologies and their integration into China. Everpower has existing graphene interests in China, and as a first step it has agreed to make a strategic investment in Haydale of £3.26 million to acquire a 9.9% of Haydale. This investment was done through Everpower's subsidiary Fu Xing New Materials Development (Heze).

UK-based Haydale has announced a collaboration agreement with Everpower International Holdings, a New York-based investment company engaged in investing in emerging technologies and their integration into China. Everpower has existing graphene interests in China, and as a first step it has agreed to make a strategic investment in Haydale of £3.26 million to acquire a 9.9% of Haydale. This investment was done through Everpower's subsidiary Fu Xing New Materials Development (Heze).

Haydale and Everpower confirmed that they have entered into non-binding heads of terms as a precursor to entering into an exclusive binding collaboration agreement to manufacture, supply and market existing Haydale products and develop nanomaterials and new graphene products for the Chinese market. Haydale’s board expected that the partners will negotiate and enter into the collaboration agreement following completion of the proposed investment.

Work on Smart Filter project commences

It was recently announced that work on the Smart Filter project, initially declared in October 2015, has begun.

It was recently announced that work on the Smart Filter project, initially declared in October 2015, has begun.

The Smart Filter project - an Innovate UK-funded project led by Haydale and involving The CPI, G2O Water Technologies and Sellafield - aims to develop a low cost self-cleaning coating technology based on functionalized graphene, which once applied to industrial membranes increases their resistance to fouling and enhances ion removal. The technology has already been demonstrated successfully in lab-scale tests.

Haydale signs joint development agreement with Huntsman Advanced Materials

Haydale Graphene Industries announced that Haydale Composite Solutions (HCS), its wholly owned subsidiary, has formally entered into a joint development agreement with Huntsman Advanced Materials. This agreement has resulted from the successful preliminary work jointly undertaken with Huntsman, to develop a range of graphene enhanced resins to complement its current product range.

Haydale Graphene Industries announced that Haydale Composite Solutions (HCS), its wholly owned subsidiary, has formally entered into a joint development agreement with Huntsman Advanced Materials. This agreement has resulted from the successful preliminary work jointly undertaken with Huntsman, to develop a range of graphene enhanced resins to complement its current product range.

The agreement provides Huntsman with the exclusive worldwide rights to market, distribute and sell a range of its resins enhanced with Haydale's functionalised graphene. This will include ARALDITE epoxy resins. The agreement will allow Huntsman to purchase Haydale's graphene enhanced masterbatches for use in the fields of composites and adhesives. Huntsman has also agreed to work exclusively with HCS to further develop graphene enhanced masterbatches with specific targeted performance characteristics.

Impressions from a visit to Haydale

A couple of weeks ago we visited Haydale's headquarters and production floor in Ammanford, Wales, UK. Here are our impressions following this visit, the meeting with Haydale's management and a visit to the production floor and processing rooms.

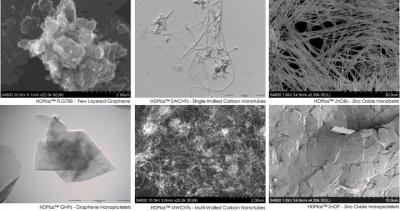

First of all, let's clear up a common misunderstanding: Haydale is not a graphene producer. It buys graphene materials (from several sources) and uses its proprietary plasma process to improve the materials, make them more uniform in quality and tailor them to specific requirements. Haydale then uses these materials to create intermediate materials - inks, coatings, composite materials (and masterbatches) and 3D filaments. Haydale is working with customers to take these materials and use them in various graphene-enhanced products.

Haydale successfully raised £500,000 to finalize the ACMC deal

Haydale recently announced that it raised around £2 million to finance an acquisition, and that it intends to raise a further £500,000. Haydale now announced that the 2nd raise was heavily over-subscribed and it successfully raise those £500,000.

Haydale is set to acquire ACMC, a US-based silicon carbide whisker manufacturer, for $7 million in a cash and shares deal, and to finance the deal Haydale raised the £2.6 million. Haydale believes that acquiring a complementary business offering significant growth potential and synergistic products is the best way to secure US business.

Haydale's HCS secures £310,000 contract extension

Haydale recently updated on the company's financial status, and has now announced that its wholly owned subsidiary, Haydale Composite Solutions, has won a 310,000 pounds ($403,000 USD) contract extension from National Grid.

Haydale recently updated on the company's financial status, and has now announced that its wholly owned subsidiary, Haydale Composite Solutions, has won a 310,000 pounds ($403,000 USD) contract extension from National Grid.

Haydale stated that the unit started designing and developing a lightweight composite gas transition piece, used to provide support and seal around steel gas transmission pipelines passing through walls. The company said that part of the contract was recognized in fiscal 2016, but that the majority of it is going to be recognized over the next 12 to 15 months.

Haydale expects to turn profitable in 2017, acquires US-based silicon carbide whisker manufacturer ACMC

Haydale reported its financial results for FY2016 (which ends in June) - the company's revenues increased to £1.92 million (up 30% from £1.48 million in 2015) - and pre-tax losses increased by the same 33% to £4 million, from £3 million in 2015.

Haydale reported its financial results for FY2016 (which ends in June) - the company's revenues increased to £1.92 million (up 30% from £1.48 million in 2015) - and pre-tax losses increased by the same 33% to £4 million, from £3 million in 2015.

In 2015, Haydale increased its staff from 32 to 46 and R&D expenses were around £1 million. Haydale expects to turn a profit in FY2017.

Haydale to acquire Thai Graphene inks & composites company

Haydale recently declared the planned acquisition of Innophene, a Thailand-based graphene-enhanced conductive ink and composites manufacturer, in an all-share deal for approximately £311,665. The acquisition marks a significant step in UK-based Haydale Graphene Industries’ expansion into the Asian market, since Innophene’s access to The Thailand Science Park in Bangkok, with its extensive analytical and processing capabilities, provides a platform for it to become the Group’s Far East Centre of Excellence.

Haydale recently declared the planned acquisition of Innophene, a Thailand-based graphene-enhanced conductive ink and composites manufacturer, in an all-share deal for approximately £311,665. The acquisition marks a significant step in UK-based Haydale Graphene Industries’ expansion into the Asian market, since Innophene’s access to The Thailand Science Park in Bangkok, with its extensive analytical and processing capabilities, provides a platform for it to become the Group’s Far East Centre of Excellence.

Innophene, founded in 2011, has developed (in conjunction with the Thailand National Science & Technology Development Agency) a one-stage exfoliation/dispersion process to create a range of graphene-enhanced transparent conductive inks for inkjet and other printing platforms. They have also now developed a graphene enhanced PLA (Poly-Lactic Acid) resin (commonly used in medical devices and 3D printing).

Experts roundup: on Graphene Oxide for composites

Last month we launched a new feature - Experts Roundup. In this feature we ask graphene professionals to answer a short graphene related question. Last month's question was "will CVD ever be a viable commercial way to produce graphene?" and we got great response to that. Hopefully this month feature will be just as good.

In the growing field of graphene-enhanced composites, especially plastics, how does graphene oxide fit in? Does it have any significant advantages over graphene?

Ian Fuller, VP business development & engineering, Angstron Materials : I would classify graphene oxide as a functionalized graphene nanomaterial. Functionalization, in general, allows for tailored nanomaterials for applications such as polymer nanocomposites. The oxygen-based groups on the surface of graphene oxide often promote coupling between the polymer and the nanomaterial leading to enhanced properties such as strength and quality of dispersion (however, electrical and thermal conductivity are often reduced). Similarly, other functional groups can be added to the surface of a graphene platelet to customize it for a range of applications and polymers.

Pagination

- Previous page

- Page 12

- Next page