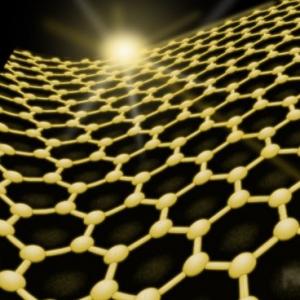

Scientists from the National Physical Laboratory in New Delhi, India developed graphene based quantum dots (GQDs) blended with organic polymers that can be used in new photovoltaics (solar) cells. This may solve the problem of toxic metals (cadmium and lead) used in today's quantum dots, and the new material is also more stable then current organic materials.

The GQDs are 9-nm in size have similar electronic properties to normal QDs, and actually perform better (less current loss and improved efficiency) because of graphene's high charge carrier mobility. This work could lead to light-weight, flexible and cheap panels - used in large-area roll-to-roll manufacturing. In fact they say that these GQDs may also be used in other applications such as OLED displays, and indeed the team fabricated OLEDs using the new material - with "good performance".