Bilayer nanographene system uses "defect" to allow ions to pass through

Würzburg University researchers have created a defect in graphene that allows ions to pass through, which could lead to new applications in water filtration or sensor technology.

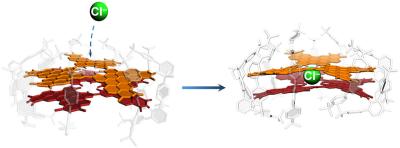

The Würzburg model system consisting of two nanographene layers that can absorb and bind chloride ions (green) through a defect in the crystal lattice. (Image: Kazutaka Shoyama / Universität Würzburg)

Defects that allow scientists to control the permeability of graphene for different substances can be very useful: ‘So-called defects can be created in the carbon lattice of graphene. These can be thought of as small holes that make the lattice permeable to gases,’ says chemistry professor Frank Würthner from Julius-Maximilians-Universität (JMU) Würzburg in Germany.