Carbon nanotubes and graphene - properties, applications and market - Page 2

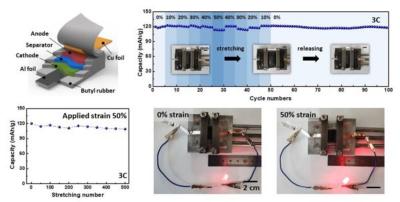

Stretchable Li-ion battery enhanced with graphene and CNTs to benefit wearable electronics

Scientists in the Korea Institute of Science and Technology (KIST) have worked with graphene and carbon nanotubes to develop a working lithium-ion battery that can be stretched by up to 50% without damage to any of the components. According to the scientists, the battery represents a significant step in the development of wearable or body-implantable electronic devices.

Rather than trying to add inherently stretchable materials such as rubber to the battery components, the group focused on creating an accordion-like structure, adding stretchability to materials that are not inherently stretchable. Using graphene and carbon nanotubes, the scientists were able to construct a honeycomb-shaped composite framework, which was then compressed inwardly like an accordion to impart the stretchable properties.

A new graphene-carbon nanotubes hybrid catalyst could help clean energy revolution

Researchers at Aalto University, collaborating with researchers at CNRS France, have developed a graphene-carbon nanotube catalyst which gives better control over important chemical reactions for producing green technology and clean energy.

The oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) are the most important electrochemical reactions that limit the efficiencies of hydrogen fuel cells (for powering vehicles and power generation), water electrolyzers (for clean hydrogen production), and high-capacity metal-air batteries. The team has developed a new catalyst that reportedly drives these reactions more efficiently than other bifunctional catalysts currently available. The researchers also found that the electrocatalytic activity of their new catalyst can be significantly altered depending on choice of the material on which the catalyst was deposited.

Rice team gives epoxy a graphene boost

Rice University scientists have developed a graphene-based epoxy for electronic applications. Epoxy combined with graphene foam invented in the Rice lab of Prof. James Tour) is reportedly substantially tougher than pure epoxy and far more conductive than other epoxy composites, while retaining the material's low density. It could improve upon epoxies in current use that weaken the material's structure with the addition of conductive fillers.

By itself, epoxy is an insulator, and is commonly used in coatings, adhesives, electronics, industrial tooling and structural composites. Metal or carbon fillers are often added for applications where conductivity is desired, like electromagnetic shielding. The trade-off, however, is that more filler brings better conductivity at the cost of weight and compressive strength, and the composite becomes harder to process. The Rice solution replaces metal or carbon powders with a 3D foam made of nanoscale sheets of graphene.

Carbon nanotubes help create reinforced graphene "rebar"

Rice University researchers have found that fracture-resistant rebar graphene is more than twice as tough as pristine graphene. While on the two-dimensional scale, graphene is stronger than steel, its extremely thin nature makes it subject to ripping and tearing. Rebar graphene is the nanoscale analog of rebar (reinforcement bars) in concrete, in which embedded steel bars enhance the material’s strength and durability. Rebar graphene, developed by the Rice lab of chemist James Tour in 2014, uses carbon nanotubes for reinforcement.

In a new study, Rice materials scientist Jun Lou, graduate student and lead author Emily Hacopian and collaborators, including Prof. James Tour, stress-tested rebar graphene and found that nanotube rebar diverted and bridged cracks that would otherwise propagate in unreinforced graphene.

First Graphene and Flinders University form a new company to commercialize VFD technology

First Graphene is collaborating with Flinders University to launch 2D Fluidics - a company that will aim to commercialize the Vortex Fluidic Device (VFD). 2D Fluidics is 50% owned by FGR and 50% by Flinders University’s newly named Flinders Institute for NanoScale Science and Technology.

First Graphene is collaborating with Flinders University to launch 2D Fluidics - a company that will aim to commercialize the Vortex Fluidic Device (VFD). 2D Fluidics is 50% owned by FGR and 50% by Flinders University’s newly named Flinders Institute for NanoScale Science and Technology.

The VFD was invented by the Flinders Institute for NanoScale Science and Technology’s Professor Colin Raston and enables new approaches to producing a wide range of materials such as graphene and sliced carbon nanotubes. The key intellectual property used by 2D Fluidics comprises two patents around the production of carbon nanomaterials, assigned by Flinders University.

Graphene and CNTs used together to create new stretchable aerogels

Researchers at Zhejiang University in China have designed a new type of aerogels, made of graphene and carbon nanotubes, that can be reversibly stretched to more than three times their original length, displaying elasticity similar to that of a rubber band. This stretchability, in addition to aerogels' existing properties like ultralow density, light weight, high porosity, and high conductivity, may lead to exciting new applications.

The scientists designed carbon aerogels consisting of both graphene and multi-walled carbon nanotubes assembled into four orders of hierarchical structures ranging from the nanometer to centimeter scale. To fabricate the material into aerogels, the researchers created an ink composed of graphene oxide and nanotubes, and then formed the aerogels via inkjet printing.

New tree-inspired electrodes could boost supercapacitors’ performance

Researchers from the UCLA, Mississippi State University, University of Nevada and China's Central South have designed an efficient and long-lasting graphene-based electrode for supercapacitors. The device’s design was inspired by the structure and function of leaves on tree branches, and it is said to be more than 10 times more efficient than other designs.

The electrode design reportedly provides the same amount of energy storage, and delivers as much power as similar electrodes, despite being much smaller and lighter. In experiments it produced 30% better capacitance — a device’s ability to store an electric charge — for its mass compared to the best available electrode made from similar carbon materials, and 30 times better capacitance per area. It also produced 10 times more power than other designs and retained 95% of its initial capacitance after more than 10,000 charging cycles.

An inexpensive, flexible pressure sensor can be used as a wearable device for various health monitoring applications

A team led by researchers from the Indian Institute of Technology (IIT) in Bombay, India, has developed a graphene-enhanced inexpensive, flexible pressure sensor that can be used for various health-care applications. The piezoresistive pressure sensor can reportedly monitor even small-scale movements caused by low-pressure variations.

The sensor can measure blood pulse rate in real time when placed on the wrist and neck. The sensor was also tested for its ability to monitor respiration; When placed on the throat, the sensor could detect changes in pressure when different words were pronounced. Interestingly, the fabricated sensor also showed good sensitivity in detecting large-scale motion monitoring, as in the case of bending and extension of finger joints.

On Nanotech Engineering's 92% efficiency graphene-CNTs solar panel claim

In early October 2017 we posted about Nanotech Engineering's novel graphene-enhanced solar panel, a post that raised many eyebrows. Nanotech says that their graphene panel reaches a 92% efficiency (compared to around 20% for large commercial silicon-based PV panels), and the cost per Watt of their panel will be 0.55 cents (compared to a US average of $3.26 for silicon PV panels).

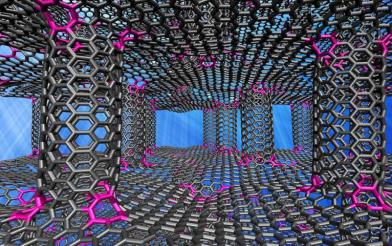

Graphene-CNT junctions (source: Rice University)

Our post quoted Nanotech's PR, stating that Jeffrey Grossman, Professor of Engineering at MIT verified the technology and said that Pound for pound, the new solar cells produce up to 1,000 times more power than conventional photovoltaics.

Researchers observe high intensity light emission from individual graphene nanoribbons

Researchers led by the CNR-Nanoscience Institute in Modena, Italy, and the University of Strasbourg in France, have experimentally observed light emission from individual graphene nanoribbons for the first time. They demonstrated that 7-atom-wide nanoribbons emit light at a high intensity that is comparable to bright light-emitting devices made from carbon nanotubes, and that the color can be tuned by adjusting the voltage. These findings may open the door to the development of bright graphene-based light sources.

Experimentally, there have been only a few demonstrations of light emission from graphene nanoribbons, and these have been limited to ensembles of nanoribbons and revealed only weak light emission. So the results of the new study, which show a much brighter light emitted by individual graphene nanoribbons compared to ensembles, hint at the exciting potential of graphene's optical properties.

Pagination

- Previous page

- Page 2

- Next page