Carbon nanotubes and graphene - properties, applications and market - Page 3

Graphene to potentially replace platinum for cheaper fuel cells

Researchers from Rice University have discovered that nitrogen-doped carbon nanotubes or modified graphene nanoribbons could potentially replace platinum, one of the most expensive facets in fuel cells, for performing fast oxygen reductionâa crucial reaction that transforms chemical energy into electricity.

The researchers used computer simulations to see how carbon nanomaterials can be improved for fuel-cell cathodes and discovered the atom-level mechanisms by which doped nanomaterials catalyze oxygen reduction reactions. The simulations also revealed why graphene nanoribbons and carbon nanotubes modified with nitrogen and/or boron are so sluggish and how they can be improved.

A new watch by Zenith to feature a graphene-CNTs hairspring

The Swiss watch manufacturer, Zenith, will be launching a new version of their longtime flagship watch, the El Primero, which will sport a hairspring based on a matrix of carbon nanotubes and graphene. The new watch will retail in the neighborhood of $10,000.

The new Defy El Primero 21 will see many upgrades and changes, among which is the use of this new graphene-enhanced composite as Zenith’s proprietary design that is highly resistant to magnetism and temperature variations like many of the best silicium examples currently in use. Like silicium parts, Zenith’s carbon hairsprings are made with a photolithography process, but one that grows the parts on a silicium wafer, rather than etching them from one. A complex series of chemical and gaseous baths and reactions grow the composite at a molecular level and give it outstanding flex characteristics.

Raymor secures over $2 million to develop graphene-enhanced li-ion batteries

Raymor Industries recently reported that it secured a $2.3 million (2.9 million CAD) grant from the Canadian government to integrate graphene into lithium-ion batteries. Raymor also manufactures carbon nanotubes for the electronics industry, and its subsidiary NanoIntegris last year launched PureWave Graphene, a substrate-free graphene grown in a plasma reactor, whose specifications are said to approach those of CVD single-layer graphene.

The $2.3 million in Sustainable Development Technology Canada funding will help the company accelerate its research and development efforts on the project, which has the potential to create batteries that perform better and last longer.

Manipulating the joints between graphene and CNTs could improve heat transfer

Researchers at Rice University have built atom-level computer models of pillared grapheneâsheets of graphene connected by covalently bonded carbon nanotubesâand discovered that manipulating the joints between the nanotubes and graphene has a significant impact on the material's ability to direct heat. The team stated that this could prove important as electronic devices shrink and require more sophisticated heat sinks.

Researchers who study or are working to make pillared graphene have primarily viewed two characteristics of the theoretical material: the length of the pillars and their distance from each other. The new study suggests that a third parameterâthe nature of the junction between the graphene and nanotubesâshould also be considered.

New graphene sensor measures high vacuum pressures

Researchers from South Korea have created a graphene nanoribbon sensor which can measure high vacuum pressures.

The Researchers synthesized a mixture of graphene nanoribbons (of varying size and chemical composition) from a combination of multi-walled carbon nanotubes, sulphuric acid and phosphoric acid in a chemical exfoliation approach. The result was a mixture of several graphene nanoribbons which were separated and purified ready for device implementation and testing. The Researchers also synthesized graphene oxide through a modified Hummers’ method for use as a reference material.

Nanotech Engineering's graphene-enhanced solar panel gains MIT's approval

Update: NanoTech Engineering's panel was not in fact verified by MIT. Read our update on nanotech's graphene solar panel here.

Nanotech Engineering announced that MIT (Massachusetts Institute of Technology) has verified the technology of its new Nanopanel, a solar panel that is declared as 92% efficient (as opposed to around 20% for traditional large panels).

Nanotech Engineering announced that MIT (Massachusetts Institute of Technology) has verified the technology of its new Nanopanel, a solar panel that is declared as 92% efficient (as opposed to around 20% for traditional large panels).

Nanotech Engineering's Nanopanel is described as a solar panel with layers of Graphene as the base, a carbon nanotube forest on top with a mineral solution that can come in any color to match the home. The panel is slightly thicker and wider than a FedEx envelope, yet stronger than steel, flexible, lightweight, flexible and about half the cost of traditional panels, said Nanotech.

Graphene-based transistor to potentially make ultra-fast computers

Researchers at the University of Central Florida, the University of Texas at Dallas and other collaborators have designed a graphene-based transistor which could be used to create an all-carbon spin logic design with the potential to someday lead to computers that are a thousand times faster and use a hundredth of the power.

The team found that by applying a magnetic field to a graphene ribbon, it is possible to change the resistance of current flowing through it. For this device, the magnetic field is controlled by increasing or decreasing the current through adjacent carbon nanotubes. Increasing or decreasing the strength of the magnetic field would also increase or decrease the flow of current through this new kind of transistor, much like a valve controlling the flow of water through a pipe.

Rice U team demonstrates a graphene-CNTs hybrid that could give Lithium batteries a major boost

Researchers at Rice University have created a rechargeable Li-ion battery, based on a hybrid of graphene and carbon nanotubes, with three times the capacity of commercial lithium-ion batteries. This was achieved mainly by addressing a major challenge known as the dendrite problem.

The Rice battery stores lithium in a unique anode made of a seamless hybrid of graphene and carbon nanotubes. The material (first created at Rice in 2012) is basically a 3D carbon surface that provides abundant area for lithium to occupy. The anode itself is said to approach the theoretical maximum for storage of lithium metal with its 3,351 milliamp hours per gram capacity, while resisting the formation of damaging dendrites or "mossy" deposits.

Updates from Prof. James Tour's graphene lab at Rice University

Prof. James Tour's research lab in Rice University is one of the leading graphene research groups in the world, with several key technologies first discovered and developed there. Professor Tour is involved with several application areas - from de-icing coating to energy storage and quantum dots production. Prof. Tour was kind enough to share his time and update us on the latest research and commercialization efforts at his lab.

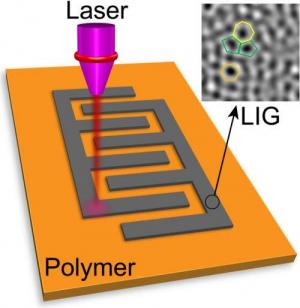

The Tour group is now commercializing two of its key technologies. First up is the laser-induced graphene (or LiG), which was reported first in 2014. This is a process in which graphene is formed on a flexible polyimide film using a room-temperature laser-based process. It is possible to pattern this graphene to create devices and as it is formed on a flexible film this easily enables flexible electronics applications.

Rice team's CNT-reinforced graphene foam is conductive and strong

Researchers at Rice University have constructed a graphene foam, reinforced by carbon nanotubes, that can support more than 3,000 times its own weight and bounce back to its original height. In addition, its shape and size are easily controlled - which the team demonstrated by creating a screw-shaped piece of the material.

The 3D structures were created from a powdered nickel catalyst, surfactant-wrapped multiwall nanotubes and sugar as a carbon source. The materials were mixed and the water evaporated; the resulting pellets were pressed into a steel die and then heated in a chemical vapor deposition furnace, which turned the available carbon into graphene. After further processing to remove remnants of nickel, the result was an all-carbon foam in the shape of the die, in this case a screw. The team said the method will be easy to scale up.

Pagination

- Previous page

- Page 3

- Next page