Graphene Coating: introduction and market status - Page 21

Grafoid enters agreement with Xiamen Tungsten to develop graphene-based applications in China

Grafoid has announced the signing of a Memorandum of Understanding (MOU) with Xiamen Tungsten of Xiamen, China, for the establishment of a strategic joint venture partnership. The agreement establishes terms for Xiamen's acquisition of up to a 20% equity position in Grafoid through the purchase of common shares - including Grafoid common shares currently held by Grafoid's affiliate, Focus Graphite, an advanced Canadian graphite mining exploration and development company.

Grafoid has announced the signing of a Memorandum of Understanding (MOU) with Xiamen Tungsten of Xiamen, China, for the establishment of a strategic joint venture partnership. The agreement establishes terms for Xiamen's acquisition of up to a 20% equity position in Grafoid through the purchase of common shares - including Grafoid common shares currently held by Grafoid's affiliate, Focus Graphite, an advanced Canadian graphite mining exploration and development company.

Focus Graphite currently holds 7.9 million Grafoid shares, and according to the MOU Xiamen can purchase up to 7 million shares from Grafoid. Seems like Focus Graphite does not want to remain a major shareholder in Grafoid - although the two companies are still linked by a 10-year offtake agreement.

Crumpled graphene may benefit self-cleaning surfaces and batteries

Researchers at Brown University have demonstrated that graphene, wrinkled and crumpled in a multi-step process, becomes significantly better at repelling water - a property that could be useful in making self-cleaning surfaces. Crumpled graphene also has enhanced electrochemical properties, which could make it more useful as electrodes in batteries and fuel cells.

The researchers aimed to build relatively complex architectures incorporating both wrinkles and crumples. To do that, the researchers deposited layers of graphene oxide onto shrink films -polymer membranes that shrink when heated. As the films shrink, the graphene on top is compressed, causing it to wrinkle and crumple. To see what kind of structures they could create, the researchers compressed same graphene sheets multiple times. After the first shrink, the film was dissolved away, and the graphene was placed in a new film to be shrunk again.

IDtechEx predicts that the graphene market will reach nearly $220 million by 2026

IDTechEx Research recently released a report that projects that the graphene market will grow to $220 million in 2026, a 10% growth from their former report that predicted that the graphene market will reach nearly $200 million by 2026. This forecast is at the material level and does not count the value of graphene-enabled products.

According to IDTechEx, a continual decline in average sales prices will accompany the revenue growth, meaning that volume sales will reach nearly 3.8 k tonnes per year in 2026. Despite this, IDTechEx forecasts suggest that the industry will remain in a state of over-capacity until 2021 beyond which time new capacity will need to be installed. Furthermore, IDTechEx Research forecasts that nearly 90% of the market value will go to graphene platelets (vs. sheets) in 2026.

Graphene's lubricity to enable frictionless coatings

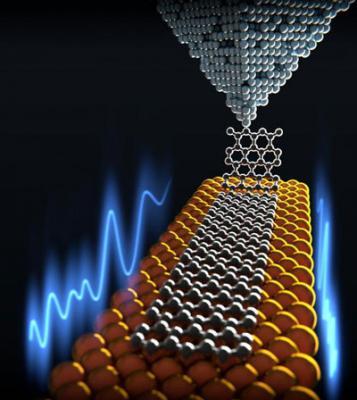

An international collaboration of scientists from the University of Basel and the Swiss Empa have studied the above-average lubricity of graphene using a two-pronged approach combining experimentation and computation. The researchers state that the results of this study help them to better understand the manipulation of chemicals at the nano level and pave the way for creating frictionless coatings.

To do this, they anchored 2D strips of carbon atoms (graphene nanoribbons) to a sharp tip and dragged them across a gold surface. Computer-based calculations were used to investigate the interactions between the surfaces as they moved across one another. Using this approach, the research team hoped to gain a better understanding of the causes of superlubricity.

Applied Graphene Materials goes into graphene-enhanced anti-corrosion paint development

UK-based Applied Graphene Materials is collaborating with US paint company Sherwin-Williams Protective and Marine Coatings, and corrosion management operation TWI Limited, in a venture to develop graphene-based anti-corrosion paints.

UK-based Applied Graphene Materials is collaborating with US paint company Sherwin-Williams Protective and Marine Coatings, and corrosion management operation TWI Limited, in a venture to develop graphene-based anti-corrosion paints.

The companies added that the scheme, co-funded by the Government’s innovation body, could have a major impact on corrosion, which is estimated to cost the UK economy about £10 billion every year in repairs on equipment used in the construction, petrochemical and transport sectors.

The Sixth Element presents its graphene-zinc anti-corrosion primer

The Sixth Element Materials, a Chinese company that focuses on R&D, mass production and sales of graphene and related materials, showcased its graphene-zinc anti-corrosion primer used for offshore wind power tower, that can come at a competitive price compared with zinc rich epoxy primer.

The Sixth Element Materials, a Chinese company that focuses on R&D, mass production and sales of graphene and related materials, showcased its graphene-zinc anti-corrosion primer used for offshore wind power tower, that can come at a competitive price compared with zinc rich epoxy primer.

The Sixth Element owns 50 & 300 t/year production lines for graphene oxide and graphene powder. Their products range from enhanced graphene, energy storage type graphene, to thermal conduction type graphene and anti-corrosion type graphene.

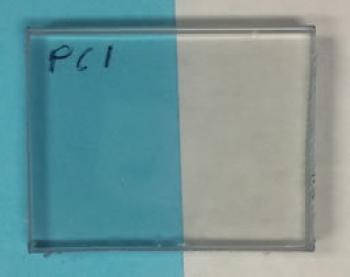

Garmor develops transparent graphene oxide films for protective coatings

Garmor, the University of Central Florida spin-off formed to develop a new graphene oxide flakes production process, has developed graphene oxide-based coatings useful for limiting UV radiation damage to sensors and polymers. Garmor’s transparent GO-films are reprtedly derived from a commercially-viable and scalable process that can be readily implemented with minimal constraints.

Four layers of GO coating on polycarbonate

Four layers of GO coating on polycarbonate

One of the most promising applications for this material is for coating plastics and polymers susceptible to UV degradation. While a single-layer GO-film maintains greater than 96% transparency in the visible spectrum, the GO-film significantly reduces the transmission of UV radiation below 360nm. Such a film could prove quite beneficial for coating a variety of products including polycarbonate automotive products, photovoltaic panels, and skylights. Transparent GO-films have great potential for use as sensors thanks, in part, to its low resistivity and UV protective coating application. Applications include use as a defogger element, integrated antenna, UV protective element in a windshield, and visor use in a disposable sensor.

A novel graphene coating could help diagnose lung cancer

A team of Chinese researchers, led by the Central China Normal University in Wuhan, has come up with a graphene-based extraction method for aldehydes from breath, which could aid in diagnosing lung cancer. This method can effectively extract hydrophobic small molecules such as aldehydes from breath while ignoring large biomolecules such as proteins, and it can also direct the extracted aldehydes straight to an HPLC system to determine its concentration.

The extraction method is based on in-tube solid-phase microextraction (IT-SPME), in which the inside of a thin tube is coated with an adsorbent material, usually some form of polymer. When a liquid sample is injected into this tube, the analytes of interest are adsorbed by the coating as the sample flows through, after which the analytes are released by a desorber for subsequent analysis. Critical to the whole process is finding a material that will effectively adsorb the analyte of interest while ignoring everything else.

Talga Resources signs collaboration agreement with Tata Steel

Talga Resources announced signing a collaboration agreement under which it, along with Tata Steel UK, will explore opportunities in graphene supply, processing and applications. The agreement links Talga’s emerging industrial scale graphene production to Tata’s growing large volume graphene coating innovations.

Talga Resources announced signing a collaboration agreement under which it, along with Tata Steel UK, will explore opportunities in graphene supply, processing and applications. The agreement links Talga’s emerging industrial scale graphene production to Tata’s growing large volume graphene coating innovations.

Initial work will have Talga supply graphene and graphitic carbon materials for use across applications in various Tata research programs including, but not limited to, anti-corrosion pigments and conductive, formable, barrier and thermal coatings.

Graphene outperforms polymer coatings in preventing microbially induced corrosion

An international research team, which included scientists from Rensselaer Polytechnic Institute, South Dakota School of Mines and Technology, Oklahoma State University, and Shenyang National Lab for Materials Science, showed that graphene can act as a promising surface coating that can be used to minimize metallic corrosion under harsh microbial conditions, and graphene coating offers 100-fold improvement in corrosion resistance compared to commercial polymer coatings available in the market while being nearly 4000 times thinner than several commercial coatings.

The researchers investigated how the microbial communities that colonize the protection system can affect the corrosion rates. Furthermore, they have used the graphene coating as a benchmark to compare to other popular polymer coatings such as Parylene and Polyurethane. Those coatings were initially promising, but failed due to various reasons including microbial attack fermentation, acid production etc. and the non-conformity of hand-applied coatings. The graphene coated Ni, however, maintained its integrity without noticeable surface corrosion.

Pagination

- Previous page

- Page 21

- Next page