An international collaboration of scientists from the University of Basel and the Swiss Empa have studied the above-average lubricity of graphene using a two-pronged approach combining experimentation and computation. The researchers state that the results of this study help them to better understand the manipulation of chemicals at the nano level and pave the way for creating frictionless coatings.

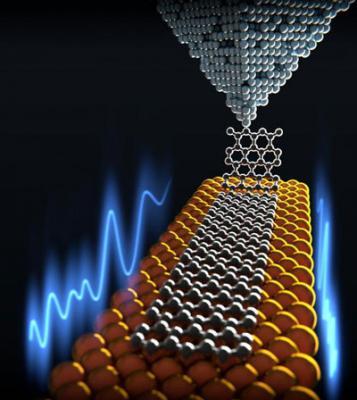

To do this, they anchored 2D strips of carbon atoms (graphene nanoribbons) to a sharp tip and dragged them across a gold surface. Computer-based calculations were used to investigate the interactions between the surfaces as they moved across one another. Using this approach, the research team hoped to gain a better understanding of the causes of superlubricity.

By studying the GNRs, the researchers hoped to learn about more than just the slip behavior. Measuring the mechanical properties of the carbon-based material also makes sense because it offers excellent potential for a whole range of applications in the field of coatings and micromechanical switches.

The experiments revealed almost perfect, frictionless movement. It is possible to move graphene ribbons with a length of 5 to 50 nanometers using extremely small forces (2 to 200 piconewtons). There is a high degree of consistency between the experimental observations and the computer simulation. A discrepancy between the model and reality appears only at greater distances (5 nanometers or more) between the measuring tip and the gold surface. This is probably because the edges of the graphene nanoribbons are saturated with hydrogen, which was not accounted for in the simulations.