Graphene Oxide: Introduction and Market News - Page 13

Will graphene oxide be the answer to mosquito bites?

A new study by Brown University shows that graphene sheets can block the signals mosquitoes use to identify a potential blood 'donor', which may enable a new chemical-free approach to mosquito bite prevention.

The researchers showed that multilayer graphene can provide a two-fold defense against mosquito bites. The ultra-thin yet strong material acts as a barrier that mosquitoes are unable to bite through. At the same time, experiments showed that graphene also blocks chemical signals mosquitoes use to sense that a blood meal is near, blunting their urge to bite in the first place. The findings suggest that clothing with a graphene lining could be an effective mosquito barrier, the researchers say.

A combination of strong and weak GO flakes can yield stronger GO paper

Researchers from Northwestern University have recently shown that graphene oxide paper can be made by mixing strong, solid GO flakes with weak, porous GO flakes. This finding may aid the production of higher quality GO materials, and also sheds light on a general problem in materials engineering: how to build a nano-scale material into a macroscopic material without losing its desirable properties.

Large single layers of GO wrinkle easily, leaving breakable gaps. Small, hard flakes don’t integrate well. image by Northwestern

Large single layers of GO wrinkle easily, leaving breakable gaps. Small, hard flakes don’t integrate well. image by Northwestern

To put it in human terms, collaboration is very important, said Jiaxing Huang, Northwestern Engineering professor of materials science and engineering, who led the study. Excellent players can still make a bad team if they don’t work well together. Here, we add some seemingly weaker players and they strengthen the whole team.

Graphene-Info's Batteries, Supercapacitors, Graphene Oxide, Lighting, Displays and Graphene Investments Market Reports updated to July 2019

Today we published new versions of all our graphene market reports. Graphene-Info provides comprehensive niche graphene market reports, and our reports cover everything you need to know about these niche markets. The reports are now updated to July 2019.

The Graphene Batteries Market Report:

- The advantages using graphene batteries

- The different ways graphene can be used in batteries

- Various types of graphene materials

- What's on the market today

- Detailed specifications of some graphene-enhanced anode material

- Personal contact details into most graphene developers

The report package provides a good introduction to the graphene battery - present and future. It includes a list of all graphene companies involved with batteries and gives detailed specifications of some graphene-enhanced anode materials and contact details into most graphene developers. Read more here!

Researchers produce graphene by mixing oxidized graphite with bacteria

Researchers at the U.S-based University of Rochester, along with colleagues at Delft University of Technology in the Netherlands, have designed a way to produce graphene materials using a novel technique: mixing oxidized graphite with bacteria. Their method is reportedly a more cost-efficient, time-saving, and environmentally friendly way of producing graphene materials versus those produced chemically, and could lead to the creation of innovative computer technologies and medical equipment.

From left to right:graphite (Gr), graphene oxide (GO), microbiallyâreduced graphene oxide (mrGO), and chemicallyâreduced graphene oxide (crGO)

From left to right:graphite (Gr), graphene oxide (GO), microbiallyâreduced graphene oxide (mrGO), and chemicallyâreduced graphene oxide (crGO)

"For real applications you need large amounts," says Anne S. Meyer, an associate professor of biology at the University of Rochester. "Producing these bulk amounts is challenging and typically results in graphene that is thicker and less pure. This is where our work came in". In order to produce larger quantities of graphene materials, Meyer and her colleagues started with a vial of graphite. They exfoliated the graphite-shedding the layers of material-to produce graphene oxide (GO), which they then mixed with the bacteria Shewanella. They let the beaker of bacteria and precursor materials sit overnight, during which time the bacteria reduced the GO to a graphene material.

Graphene and bacteria combine to create a powerful electrocatalyst

Researchers from KAUST show that microbes and nanomaterials like graphene can be used together to form a biohybrid material that performs well as an electrocatalyst. The team says that such materials could be used in the solar-powered production of carbon-free fuels and several other green-energy applications.

A process called the oxygen-evolution reaction (OER) is at the heart of many clean energy technologies. In the case of solar-fuel production, for example, the OER enables the use of solar electricity to split water molecules into oxygen and hydrogen, producing clean hydrogen that can be used as a fuel. Currently, rare and expensive metals are used as OER electrocatalysts. However, graphene-based biohybrid materials could make an inexpensive, eco-friendly alternative, as the team at KAUST has shown.

GrapheneCA launches Mobile Graphene Container System for in-house graphene manufacturing

GrapheneCA recently announced the development of a novel Mobile Graphene Container System (MGCS), a scalable, modular graphene production system, to help companies manufacture graphene in-house.

The New York-based company, which develops graphene-based technology for industries, said MGCS is available in 40-foot containers that are designed specifically for industrial producers and high-tech applications.

Graphene Leaders Canada provides financial and commercial updates

Graphene Leaders Canada (GLC) has announced that it has been awarded $350,000 CAD (around $261,000 USD) grant funding for a joint project under the National Research Council United Kingdom (UK) Research Institute (NRC-UKRI) Research and Innovation Program. This funding will support GLC’s Scaling of Graphene Oxide towards the development of GLC’s Environmental platform of products.

Graphene Leaders Canada (GLC) has announced that it has been awarded $350,000 CAD (around $261,000 USD) grant funding for a joint project under the National Research Council United Kingdom (UK) Research Institute (NRC-UKRI) Research and Innovation Program. This funding will support GLC’s Scaling of Graphene Oxide towards the development of GLC’s Environmental platform of products.

This project will support scale up activities of graphene oxide with a focus on developing a cost effective, scalable production method aimed at commercializing our environmental platform of products for air and water treatment, said Dr. Leah Coumont, GLC’s Director of R&D.

Graphene oxide layers made to mimic biological channels may clean up pharmaceuticals production

KAUST researchers have tailored the structure of graphene-oxide layers to mimic the shape of biological channels, creating ultra-thin membranes to rapidly separate chemical mixtures. This may have the potential to inspire new materials to clean up chemical and pharmaceutical production.

"In making pharmaceuticals and other chemicals, separating mixtures of organic molecules is an essential and tedious task," says Shaofei Wang, postdoctoral researcher in Suzana Nuñes lab at KAUST. One option to make these chemical separations faster and more efficient is through selectively permeable membranes, which feature tailored nanoscale channels that separate molecules by size.

Graphene oxide assists in purifying water without chlorination

Scientists from the National University of Science and Technology "MISIS" together with their colleagues from Derzhavin Tambov State University and Saratov Chernyshevsky State University have shown a way for graphene oxide to purify water, making it drinkable, without further chlorination. "Capturing" bacterial cells, it forms flakes that can be easily extracted from the water.

1) Graphene oxide, added in water 2) Water after purification with graphene oxide 3) Graphene oxide 'flakes' with bacteria before extraction

1) Graphene oxide, added in water 2) Water after purification with graphene oxide 3) Graphene oxide 'flakes' with bacteria before extraction

The team has conducted an experiment, injecting graphene oxide into solutions (nutrient medium and the saline) containing E.coli. Under the terms of the experiment, saline "simulated" water, and the nutrient medium simulated human body medium. The results showed that the graphene oxide along with the living and the destroyed bacteria form flakes inside the solutions. The resulting mass can be easily extracted, making water almost completely free of bacteria. If the extracted mass is then treated with ultrasound, the graphene can be separated and reused.

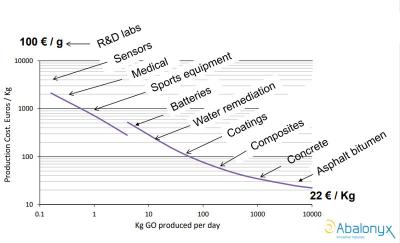

Abalonyx reports strong revenue growth in 2018

Norway-based Graphene Oxide developer Abalonyx reports that its graphene oxide sales have increased by about 80 % in 2018, and this follows a 70% increase in 2017 compared to 2016. The company expects to see further strong sales growth in 2019.

Abalonyx says that over 90% of its sales derive from returning industrial partners. The company also revealed two of these customers: ORA Graphene Audio with its GO membranes and Provexa AB which developed an anti-corrosion protection coating that is now being used on Scania trucks.

Abalonyx says that over 90% of its sales derive from returning industrial partners. The company also revealed two of these customers: ORA Graphene Audio with its GO membranes and Provexa AB which developed an anti-corrosion protection coating that is now being used on Scania trucks.

Pagination

- Previous page

- Page 13

- Next page