Graphene applications: what is graphene used for?

Graphene is a one-atom-thick sheet of carbon atoms arranged in a honeycomb-like pattern. Graphene is considered to be the world's thinnest, strongest and most conductive material - of both electricity and heat. All of these properties are exciting researchers and businesses around the world - as graphene has the potential to revolutionize entire industries - in the fields of electricity, conductivity, energy generation, batteries, sensors and more.

Mechanical strength

Graphene is the world's strongest material, and can be used to enhance the strength of other materials. Dozens of researchers have demonstrated that adding even a trace amount of graphene to plastics, metals or other materials can make these materials much stronger - or lighter (as you can use a smaller amount of material to achieve the same strength).

Such graphene-enhanced composite materials can find uses in aerospace, building materials, mobile devices, and many other applications.

Thermal applications

Graphene is the most heat conductive found to date. As graphene is also strong and light, it means that it is a great material for making heat-spreading solutions, such as heat sinks or heat dissipation films. This could be useful in both microelectronics (for example to make LED lighting more efficient and longer lasting) and also in larger applications - for example thermal foils for mobile devices. Huawei's latest smartphones, for example, have adopted graphene-based thermal films.

Energy storage

Since graphene is the world's thinnest material, it also extremely high surface-area to volume ratio. This makes graphene a very promising material for use in batteries and supercapacitors. Graphene may enable batteries and supercapacitors (and even fuel-cells) that can store more energy - and charge faster, too.

The advantages of graphene batteries

The advantages of graphene batteries

Coatings ,sensors, electronics and more

Graphene has a lot of promise for additional applications: anti-corrosion coatings and paints, efficient and precise sensors, faster and efficient electronics, flexible displays, efficient solar panels, faster DNA sequencing, drug delivery, and more.

Graphene is such a great and basic building block that it seems that any industry can benefit from this new material. Time will tell where graphene will indeed make an impact - or whether other new materials will be more suitable.

Sparc to trial graphene-based coating with BHP Mitsubishi Alliance at Goonyella Riverside Mine

Sparc Technologies has announced the execution of an agreement (Trial Agreement) with BHP Mitsubishi Alliance (BMA). The Trial Agreement details the terms and conditions under which Sparc and BMA will conduct a collaborative field trial involving testing of an ecosparc® enhanced coating in coal handling and processing plant (CHPP) infrastructure at the Goonyella Riverside Mine (GRM) in Queensland.

The Trial Agreement with BMA represents a continuation of Sparc’s strategy of working with asset owners across government, defense, mining and oil & gas to demonstrate the performance of ecosparc® enhanced coatings in relevant real-world environments. The temperature, moisture and conditions within the CHPP at GRM, located in Moranbah, Queensland are well suited for an effective field trial. The field trial will provide valuable performance data for potential customers, building on over 6 years of research and development and >10,000 data points from accelerated cyclic corrosion testing in the laboratory.

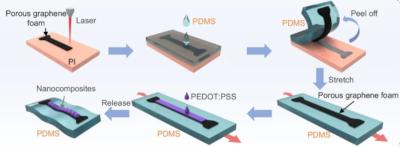

Laser-induced graphene-based sensor can separately measure temperature and physical strain

Researchers at Penn State and Hebei University of Technology recently developed stretchable thermoelectric porous graphene foam-based materials via facile laser scribing for self-powered decoupled strain and temperature sensing. The new sensor material enables precise and separate measurement of temperature and physical strain, a vital development for biosensors, for accurately tracking various health signals.

The team’s innovation is based on laser-induced graphene (LIG), created by using a laser to convert carbon-rich materials, such as plastic or wood, into graphene by heating their surfaces. This simple and scalable process is already used in a variety of applications, including gas sensors and electrochemical detectors. However, the scientists believe they have uncovered a new, critical property of LIG that makes it ideal for multi-signal sensing.

New graphene-based method could improve DNA sequencing

A new graphene-based method could make for faster, cheaper and more accurate DNA sequencing, according to a group of Leiden scientists. The research team has received EUR 1.2 million through the Dutch Research Council (NWO) Open Technology program to develop their new method.

The new DNA sequencing method builds on a previous Leiden discovery in which the research groups of chemist Grégory Schneider and physicist Jan van Ruitenbeek got an electrical current to jump across two layers of graphene, each an atom thick. By bringing the two layers close together at a certain angle, they caused tunnelling to occur. This is a quantum mechanical phenomenon where electrons jump from one material to another despite there being no direct contact between the two.

Philips to launch new noise-canceling headphones with graphene coated drivers

Philips has announced its new noise-canceling headphones, the Philips H8000E.

Image credit: Philips and techradar

The new product will be a mid-range offering on Philips' product list, and the wireless, over-ear device will come with adaptive Adaptive Noise Cancellation (ANC). Inside, there are graphene-coated 40mm drivers that allow for high-resolution playback and Spatial Audio functionality.

Hydrograph and Arizona State University report positive research results for Fractal Graphene's potential to enhance cement performance

HydroGraph Clean Power has announced its second research study in partnership with Arizona State University (ASU) highlighting the advancements in extending the use of HydroGraph’s Fractal Graphene™ into cement and concrete applications.

The report reportedly validates the potential of HydroGraph’s graphene for the construction industry, with graphene-enhanced concretes offering practical and sustainable options for high-performance applications, from ultra-strong construction materials to cutting-edge 3D printing techniques.

Novel graphene-based biosensing platform simultaneously detects vitamin C and SARS-CoV-2

Researchers from Penn State recently developed a portable and wireless device to simultaneously detect SARS-CoV-2, the virus that causes COVID-19, and vitamin C, a critical nutrient that helps bolster infection resistance, by integrating commercial transistors with printed laser-induced graphene.

By simultaneously detecting the virus and vitamin C levels, the test could help individuals and their health care providers decide on more effective treatment options, the researchers said. For example, someone with low vitamin C levels may benefit from a supplemental boost, while someone with normal or high vitamin C levels may need to consider other options.

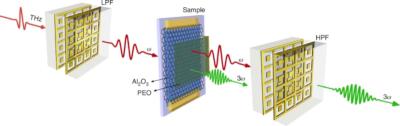

New method enhances frequency conversion processes in graphene

Researchers from Canada's University of Ottawa, Iridian Spectral Technologies and University of Bayreuth in Germany have developed combined methods to enhance THz nonlinearities in graphene-based structures. The team's innovative methods aim to enhance frequency conversion of terahertz (THz) waves in graphene-based structures, unlocking new potential for faster, more efficient technologies in wireless communication and signal processing.

Schematic of the experimental configuration at the sample position to generate and detect THz third harmonic generation. Image from: Light: Science & Applications

THz waves, located in the far-infrared region of the electromagnetic spectrum, can be used to perform non-invasive imaging through opaque materials for security and quality control applications. Additionally, these waves hold promise for wireless communication. Advances in THz nonlinear optics, which can be used to change the frequency of electromagnetic waves, are essential for the development of high-speed wireless communication and signal processing systems for 6G technologies and beyond.

Will Apple's iPhone 17 lineup use graphene cooling tech?

Various reports suggest that the entire iPhone 17 lineup, including the iPhone 17, iPhone 17 Air, iPhone 17 Pro, and iPhone 17 Pro Max, will use a heat dissipation technology called "vapor chamber (VC) cooling system". It is not quite clear, however, which of these models will use combined VC technology and graphene sheets, and which will use only one of these thermal management technologies.

As the iPhone 15 Pro is known to face overheating issues, Apple turned to using graphene sheets in the thermal system when launching the iPhone 16 Pro. To further enhance the cooling mechanism, iPhone 17 models may also adopt vapor chamber technology.

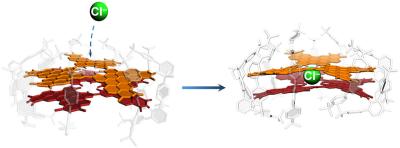

Bilayer nanographene system uses "defect" to allow ions to pass through

Würzburg University researchers have created a defect in graphene that allows ions to pass through, which could lead to new applications in water filtration or sensor technology.

The Würzburg model system consisting of two nanographene layers that can absorb and bind chloride ions (green) through a defect in the crystal lattice. (Image: Kazutaka Shoyama / Universität Würzburg)

Defects that allow scientists to control the permeability of graphene for different substances can be very useful: ‘So-called defects can be created in the carbon lattice of graphene. These can be thought of as small holes that make the lattice permeable to gases,’ says chemistry professor Frank Würthner from Julius-Maximilians-Universität (JMU) Würzburg in Germany.

ADNOC Gas and Baker Hughes install Levidian's LOOP technology at their operational gas processing plant

ADNOC Gas and Baker Hughes have installed Levidian’s LOOP technology at the Habshan Gas Processing Plant. The Gulf operator claims it marks the first-ever deployment of the technology at an operational gas processing site.

Carbon will be captured from methane, the main constituent of natural gas, and transformed into graphene, as part of a pilot trial. The LOOP unit is capable of producing more than 1 tonne per annum (tpa) of graphene and 1 tpa of hydrogen, making it a dual-purpose innovation aligned with global energy transition goals. Future industrial-scale installations are expected to deliver 15 tpa.

Pagination

- Page 1

- Next page