Researchers at Penn State and Hebei University of Technology recently developed stretchable thermoelectric porous graphene foam-based materials via facile laser scribing for self-powered decoupled strain and temperature sensing. The new sensor material enables precise and separate measurement of temperature and physical strain, a vital development for biosensors, for accurately tracking various health signals.

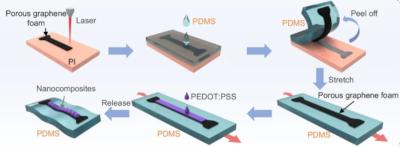

The team’s innovation is based on laser-induced graphene (LIG), created by using a laser to convert carbon-rich materials, such as plastic or wood, into graphene by heating their surfaces. This simple and scalable process is already used in a variety of applications, including gas sensors and electrochemical detectors. However, the scientists believe they have uncovered a new, critical property of LIG that makes it ideal for multi-signal sensing.

The team stated that the fact that this material also has thermoelectric properties is the key for their innovation, as it is important for separately measuring both temperature changes and physical strain or deformation. Thermoelectric properties allow a material to convert temperature differences into electrical voltage, which is essential for both temperature sensing and energy harvesting. By exploiting this property, the team was able to distinguish between temperature changes and physical strain in their sensor.

However, when materials that are sensitive to both temperature and strain can have the issue of how to tell which signal is causing changes in the material. But by using this thermoelectric effect in the laser-induced graphene, the scientists can essentially decouple those two measurements. They can look at the electrical resistance to get information about the strain, while also measuring the thermal voltage to determine the temperature. This is why doctors could use it to track both temperature fluctuations and physical changes in the wound site and give a much clearer picture of how the healing is progressing.

The team also highlighted that the sensor is highly sensitive, capable of detecting temperature variations as minor as 0.5 ºC. The design of the material leverages the interaction between porous graphene and thermoelectric components, enhancing its efficiency in converting heat into electricity by nearly four times. Additionally, the sensor can stretch up to 45% and adapt to various shapes and surfaces without compromising functionality.

It was explained that the porous structure of this material creates a lot of tiny spaces and channels that allow it to interact with its surroundings in a very sensitive way. This makes it well-suited for interfacing with human soft tissues, in contrast to more rigid thermoelectric materials, such as ceramic-based ones.

Since the thermoelectric aspect of LIG also means it can generate electrical power when there is a temperature difference, LIG sensors are self-powered. This could be particularly useful for continuous monitoring in clinical settings and for other applications, such as helping detecting fires in remote locations.

In addition to enhancing the sensor, the research team is working on a wireless system that will enable remote monitoring of sensor data. This advancement will facilitate real-time tracking of critical information, such as temperature or strain, via smartphones or other devices.