Researchers at Tsinghua University, Zhejiang University and Zhejiang Sanhua Intelligent Controls Co., have designed a graphene-based thermal-switching material for improving the safety of lithium-ion batteries (LIBs) by making sure that they can safely operate at different temperatures and do not explode when overheated.

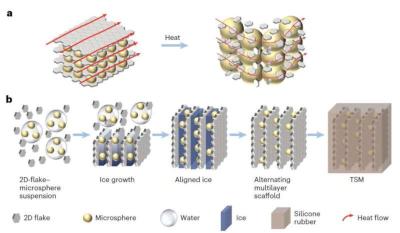

a) Thermal-switching mechanism of the TSM. b) The self-assembly process through freeze-casting of 2D-flake–microsphere suspensions to form an alternating multilayer scaffold together with polymer infiltration. Image credit: Nature Energy

A general approach to improving the safety of LIBs is using thermal-conducting interlayers, materials designed to even out the temperature between a battery's modules, bringing it to between 15 to 45 °C. To ensure that a high-capacity LIB is safe, these materials should be highly thermally insulating, thus preventing the propagation of heat, while also ensuring that temperature is uniformly distributed in the battery. The research team's newly developed thermal-switching material meets both criteria, and can effectively regulate the temperature in high-capacity batteries. This material rapidly responds to temperature, enabling the safe cycling of batteries in varying operating conditions.

"Effective thermal safety management relies on the thermal conductivity of interlayer materials, yet current designs lack the needed responsiveness for both performance and safety", the scientists wrote in their paper. "We design a thermal-switching material with high switching ratio from thermal conduction to thermal insulation state to address this predicament."

The thermal-switching material designed by the team is comprised of microspheres embedded between connected graphene layers. Notably, the microspheres expand in volume in response to changes in temperature.

The microspheres' temperature-sensitive expansion disrupts the transport of heat by separating neighboring 2D graphene layers. In turn, this helps to regulate the temperature inside battery cells, preventing them from exploding.

To evaluate the performance of the material, the researchers integrated it into a 50 Ah Ni–Co–Mn LIB, using it as a cell-to-cell interlayer. Their findings were highly promising, as the material was found to successfully act as a thermal regulator, preventing the propagation of heat and chain reactions that could lead to explosions.

"The designed thermal-switching material exhibits a wide temperature range for heat conduction (1.33 W m−1 K−1 at room temperature) and can transform to an adiabatic state within 30 s (0.1 W m−1 K−1 at around 100 °C) when heated," the team wrote.

"When applied as cell-to-cell interlayers for a module with four 50 Ah nickel–cobalt–manganese lithium-ion cells, the material not only ensures a uniform temperature distribution under normal working conditions, but more importantly prevents 80% of the heat transmission from thermal runaway, effectively avoiding catastrophic battery explosion."

The new thermal regulator introduced by this research team could be implemented and tested on other high-capacity batteries. In the future, it could contribute to the widespread commercialization and use of these batteries, ensuring their safety in varying climates on Earth and at different operating conditions.

"We believe that this thermally responsive material design will ensure safety and high performance throughout the lifespan of high-energy-density battery modules," said the researchers.