Graphene 3D printing: introduction and market status

3D printing (or additive manufacturing) refers to a process in which a 3D printer is used for stacking layers of material under computer control, following a 3D model (or other electronic data source), resulting in a printed three-dimensional object.

Various applications for 3D printing include design visualization and prototyping, metal casting, architecture, education, healthcare, entertainment and more. As 3D printing technology continues to evolve and develop, researchers imply possible biotechnological uses like bio-printing and computer-aided tissue engineering as well as retail manufacturing of custom end products which might change the face of commerce.

A large number of 3D printing processes exist nowadays, differing mainly in their methods of layering and the materials that are used. Some methods melt or soften material to produce layers while others use liquid materials or thin layers of material that are cut to shape and joined together. 3D printing materials are varied, and include Thermoplastics, HDPE, Rubber, edible materials, clay, metal alloy, and more. New technologies, such as infusing carbon fibers into plastics, allow for a stronger, lighter material.

Graphene, a single-atomic layer of carbon atoms arranged in a hexagonal lattice, is repeatedly dubbed a “wonder material†due to its immense array of uncanny properties like extraordinary conductivity, flexibility and transparency.

Graphene-enhanced nanocomposite materials greatly improve traditional materials used in 3D printing, like plastics. Graphene nanoplatelets that are added to polymers make materials that are mechanically stronger and with improved thermal and electrical conductivity.

Graphene 3D Lab, a joint-venture between Graphene Labs and Lomiko Metals, is one of the leaders in this new market. The company's founder and COO, Dr. Elena Polyakova comments in an interview for Graphene-info on the advantages of graphene-based materials over current 3D printing materials: “Fused Filament Fabrication (FFF) -- a method of 3D printing in which filament is extruded layer by layer to create objects -- capabilities are currently bound by the offerings of filaments, which generally includes non-functional thermoplastics. While such plastics are great for printing desktop models and fascinating gadgets, the real-world applications of printing with such filaments by themselves are limited. By creating a line of materials with functional properties, the capabilities of FFF 3D printers will be greatly expanded.

Graphene 3D Lab, a joint-venture between Graphene Labs and Lomiko Metals, is one of the leaders in this new market. The company's founder and COO, Dr. Elena Polyakova comments in an interview for Graphene-info on the advantages of graphene-based materials over current 3D printing materials: “Fused Filament Fabrication (FFF) -- a method of 3D printing in which filament is extruded layer by layer to create objects -- capabilities are currently bound by the offerings of filaments, which generally includes non-functional thermoplastics. While such plastics are great for printing desktop models and fascinating gadgets, the real-world applications of printing with such filaments by themselves are limited. By creating a line of materials with functional properties, the capabilities of FFF 3D printers will be greatly expanded.

By way of example, filaments infused with graphene can be conductive and much more durable than non-specialized filaments, features which are necessary for a host of applications. We also intend to develop filaments with other functional properties, including magnetic capabilities.†as per Dr. Polyakova's words, Graphene 3D Lab is funded to begin production of printing filaments in the near future, and is working towards a target of reaching commercial production around the first half of 2015.

Graphene 3D Labs also plans to produce 3D printable batteries, based on graphene. These batteries can potentially outperform current commercial batteries, and will come in shapes and sizes that can be tailored to match the designs of specific devices. The company already unveiled a prototype battery in October 2014. In March 2015 G3L announced that it has launched commercial sales of its conductive graphene filament for 3D printing. The filament incorporates highly conductive proprietary nanocarbon materials to enhance the properties of PLA, a widely used thermoplastic material for 3D printing. The filament is therefore compatible with most commercially available 3D printers. In June 2015, the company announced the signing of a Memorandum of Understanding with Ideum, a company which develops large-scale smart-tables and walls. The agreement lays the foundation for joint research, product development, and marketing between the two companies. Graphene 3D and Ideum will evaluate and co-develop products by Graphene 3D which can be used as capacitive sensors to interface with Ideum's products. Graphene 3D will also begin commercial on-demand 3D printing of coasters, joysticks, and styluses which Ideum clients can use to interact with their smart-tables. For example, styluses of various shapes, 3D printed in Conductive Graphene Filament, may be used as brushes used in photo editing software to give a more hands-on feel to creative work done on an Ideum smart-table.

In May 2015, researchers at Northwestern University designed a method to print 3D structures using graphene nanoflakes, by developing a graphene-based ink that can be used to print large, robust 3D structures. This fast and efficient method may open up new opportunities for using graphene printed scaffolds and various other electronic or medical applications. Also in May 2015, researchers at Michigan Technological University progressed in their work to 3D print replacement nerves using 3D bioprinting techniques. The team has developed polymer materials that can act as a scaffold for growing tissues and is working on integrating graphene as the electrical conductor.

In March 2015, U.S-based Local Motors declared plans to 3D print vehicles within 12 hours, reinforcing extruded printed material with graphene. The company reported significant progress in its additive manufacturing technology since it unveiled its Strati vehicle. The company was looking to reduce the print time to 12 hours, with a four to five-hour assembly time, and had been speaking to a Korean firm about sourcing graphene for extruding in composite 3D printing materials.

In July 2014, US-based Graphene Technologies announced a partnership with Stratasys to co-develop graphene-enhanced 3D printing materials.

A 12X12 meter 3D graphene-fiberglass printer was unveiled by Qingdao Unique Products Develop during a trade show in China. It is meant to print building in the future, according to the company, using a fiberglass-graphene composite that will allow the creation of very strong objects.

Grafoid, a Canadian based company, signed an agreement with Altamat to construct an atomization facility to produce MesoGraf graphene-based powders and filaments for 3D printing for use in a wide range of functionalized powders for 3D printing applications. Grafoid hopes to supply a wide range of Mesograf-based powders and filaments that will allow manufacturing companies in every industry to utilize additive manufacturing processes to produce their end products on demand, not solely for prototyping purposes.

Australian company 3D Graphtech Industries, established by CSIRO organization to investigate research opportunities in 3D printing using graphite and graphene inks, will jointly perform a white-paper study to identify technological problems in the 3D printing market that can be solved in an R&D program to provide a commercial solution.

US based AGT launched a similar research project in collaboration with Ukraine's Kharkiv Institute of Physics and Technology ("KIPT").

Further reading

- Introduction to graphene

- Graphene company database

- How to invest in the graphene revolution

- The Graphene Handbook, our very own guide to the graphene market

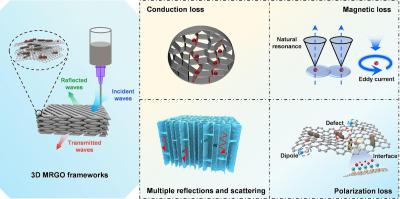

Researchers 3D print unique graphene frameworks for enhanced EMI shielding

Researchers from China's Nanjing University of Science and Technology and Chinese Academy of Sciences (CAS) have developed lightweight and structurally controllable 3D reduced graphene oxide frameworks decorated with magnetic components (MRGO frameworks) via 3D printing technology to tailor EMI shielding properties.

The team explains that by adjusting the preparation conditions of the MRGO frameworks, such as inter-filament spacing, composition, and pyrolysis temperature, the graphitization degree and transmission paths are influenced, enabling electrical conductivity and magnetic property, and ensuring excellent EMI shielding performance.

Researchers develop graphene-enhanced 3D-printed concrete

Researchers from the University of Virginia, Virginia Transportation Research Council and Turkey's Istanbul Technical University have developed a more sustainable, printable cementitious composite. This new material combines graphene with limestone and calcined clay cement (LC2), and is said to offer enhanced strength and durability while significantly reducing carbon emissions.

"Our goal was to design a printable concrete that performs better and is more eco-friendly," said Osman Ozbulut, a professor at UVA's Department of Civil and Environmental Engineering. "The addition of graphene to LC2 cement offers a unique opportunity to lower carbon emissions while maintaining the strength and flexibility required for 3D printed construction."

Versarien and Balfour Beatty to jointly develop graphene-infused 3D-printable mortars for civil construction

Versarien has announced that it has signed an agreement with Balfour Beatty Group to develop a range of low carbon, graphene-infused, 3D-printable mortars suitable for civil construction.

This will include formulating three types of mortar: one based on local materials, and two enhanced with Versarien's graphene admixture, Cementene. Additionally, efforts will focus on establishing a UK-based supply chain, involving identifying local suppliers, integrating the graphene admixture, implementing quality control protocols, and creating distribution channels and sales frameworks for both domestic and international markets.

Versarien enters 3D construction printing contract with Building For Humanity

Versarien has announce that the Company has entered into a contract with Building For Humanity for Versarien to act as a 'print partner' to support Building For Humanity CIC, a community interest company, with a range of services for its flagship Charter Street project in Accrington, Lancashire. The contract, initially valued at approximately £200,000 will see Versarien providing 3D construction printing ("3DCP") input at all stages of the project, giving Building For Humanity a full service from design to construction.

It was disclosed that the Company had previously signed a letter of mutual commitment to support the Charter Street project. The contract now signed follows the formal commencement of the project, which will see the development of 46 high-quality affordable homes, in five blocks, along with associated infrastructure, including a community hub, led by Building For Humanity. The initial phase of the project will involve the construction of the first housing block and the community hub.

Researchers develop improved graphene micro supercapacitors for wearables

Researchers from China University of Petroleum (East China), Henan Agricultural University and Chinese Academy of Sciences have developed an additive-free 3D printing process to construct graphene micro-supercapacitors (MSCs) with unprecedented electrochemical properties and seamless integrability. The team states that this achievement overcomes existing manufacturing limitations and brings closer the on-chip MSC arrays essential for the next generation of wearables.

Wearable devices require ever-smaller on-board energy solutions that can deliver bursts of power while remaining unobtrusive. Rigid coin batteries restrict device flexibility and ergonomics. Leading microscale alternatives include micro-supercapacitors (MSCs), which store and discharge energy rapidly owing to highly porous electrode materials interfacing with electrolytes. Supercapacitors’ quick charge ability and resilience to repeated charging cycles make them appealing to supplement batteries. However, difficulties producing intricately designed MSC devices that also offer high performance have confined MSCs to the lab. Conventional manufacturing techniques often lack suitable precision, flexibility, and scalability.

Researchers examine the use of graphene oxide to strengthen 3D-printed concrete

Researchers at Australia's RMIT University and University of Melbourne have investigated the effectiveness of graphene oxide (GO) sheets in enhancing the compressive strength of 3D-printed cementitious mortar.

They added graphene oxide to the cement used as a binder in 3D-printed concrete. After experimenting with different amounts, it was found that when graphene oxide was added at a dosage of 0.015% the weight of the cement, the resulting concrete exhibited better inter-layer bonding. This boost produced a 10% increase in overall strength.

Nova Graphene to develop graphene-enhanced armor for service animals

Nova Graphene has announced a pivot in their product development strategy. Originally focused on designing 3D-printed graphene-enhanced ballistic armor for human military and law enforcement personnel, Nova has now fast-tracked the development of similar armor specifically designed for service animals.

The team at Nova Graphene decided to expedite animal scanning and prototyping while conducting an early body scan test for their current armor project.

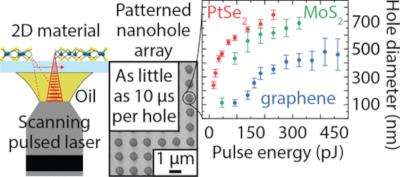

Researchers pattern 2D materials using a commercial two-photon 3D printer

Researchers from the University of the Bundeswehr Munich & SENS Research Center and KTH Royal Institute of Technology recently demonstrated the noncontact and resist-free patterning of platinum diselenide (PtSe2), molybdenum disulfide (MoS2), and graphene layers with nanoscale precision at high processing speed while preserving the integrity of the surrounding material.

The team used a commercial, off-the-shelf two-photon 3D printer to directly write patterns in the 2D materials with features down to 100 nm at a maximum writing speed of 50 mm/s.

Researchers develop multi-material printer that enables quick and easy 3D printing of flexible devices

Scientists from Nanyang Technological University (NTU), Panasonic Factory Solutions Asia Pacific Pte. Ltd. (Panasonic) and Singapore Centre for 3D Printing (SC3DP) have developed a multi-material printer using multi-wavelength high-power lasers, for quick and easy 3D printing of smart, flexible devices.

The multi-material printer works by utilizing varying wavelengths of laser, creating thermal and chemical reactions capable of transforming common carbon-based materials (polyimide and graphene oxide) into a new type of highly porous graphene. The resulting structure printed with this new graphene is not only light and conductive, but it can also be printed or coated onto flexible substrates like plastics, glass, gold and fabrics, creating flexible devices.

Evove secures over $6.7 million to advance its graphene-based for its water filtration technology

UK-based Evove, developer of a graphene-based water filtration technology designed to tackle water shortage, has announced that it has secured £5.7 million (around USD$6,750,000) in a round of funding led by One Ventures with participation from AM Ventures and existing investors.

Evove says it will use the funds to expand its manufacturing capacity, scale up its 3D-printed membrane process, and capitalize on its substantial pipeline of opportunities.

Pagination

- Page 1

- Next page