Sparc to trial graphene-based coating with BHP Mitsubishi Alliance at Goonyella Riverside Mine

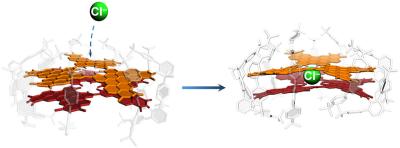

Sparc Technologies has announced the execution of an agreement (Trial Agreement) with BHP Mitsubishi Alliance (BMA). The Trial Agreement details the terms and conditions under which Sparc and BMA will conduct a collaborative field trial involving testing of an ecosparc® enhanced coating in coal handling and processing plant (CHPP) infrastructure at the Goonyella Riverside Mine (GRM) in Queensland.

The Trial Agreement with BMA represents a continuation of Sparc’s strategy of working with asset owners across government, defense, mining and oil & gas to demonstrate the performance of ecosparc® enhanced coatings in relevant real-world environments. The temperature, moisture and conditions within the CHPP at GRM, located in Moranbah, Queensland are well suited for an effective field trial. The field trial will provide valuable performance data for potential customers, building on over 6 years of research and development and >10,000 data points from accelerated cyclic corrosion testing in the laboratory.