Graphene batteries: Introduction and Market News - Page 2

Infinity Turbine introduces 3D-printed electrodes for Salgenx saltwater batteries and electrocatalyst applications

Infinity Turbine, developer of sustainable energy storage solutions, has unveiled an approach to electrode fabrication that combines fiber laser heat treating, 3D additive manufacturing, and laser-induced carbonization. This synergistic technology enables the direct transformation of carbon-rich materials like sugar and wood fibers (including bamboo) into hard carbon or graphene-like structures. The resulting 3D-printed electrodes are set to revolutionize the manufacturing of Salgenx saltwater flow batteries, gas processing, and electrocatalyst applications.

Salgenx is developing saltwater flow batteries as a solution for safe, environmentally friendly grid-scale energy storage. With the introduction of 3D-printed carbon electrodes, Infinity Turbine can enhance the battery’s efficiency by providing a high-conductivity, high-surface-area electrode structure. The combination of laser-induced graphene and tailored 3D-printed geometries reportedly allows for faster ion exchange, improved energy density, and longer battery life, all while using sustainable, carbon-rich materials. The concept of a 3D printed electrode reduces manufacturing time and complexity, resulting in more efficient electrode production with just-in-time (JIT) technology integration and decreased inventory costs.

Manchester University team discovers energy storage mechanism in bi-layer graphene anode

A team of scientists from the University of Manchester has gained new understanding of lithium-ion storage within the thinnest possible battery anode - composed of just two layers of carbon atoms. Their work shows an unexpected ‘in-plane staging’ process during lithium intercalation in bilayer graphene, which could pave the way for advancements in energy storage technologies.

Lithium-ion batteries, which power everything from smartphones and laptops to electric vehicles, store energy through a process known as ion intercalation. This involves lithium ions slipping between layers of graphite - a material traditionally used in battery anodes, when a battery is charged. The more lithium ions that can be inserted and later extracted, the more energy the battery can store and release. While this process is well-known, the microscopic details have remained unclear. The Manchester team’s discovery sheds new light on these processes by focusing on bilayer graphene, the smallest possible battery anode material.

Graphene Manufacturing Group gives update, says its Richlands plant "exceeds hopes"

Graphene Manufacturing Group (GMG) has provided a business update on its recently commissioned modular graphene production plant at Richlands, Australia. The graphene production plant has been operating and producing graphene since its commissioning date in December, 2023.

The performance of the production unit, according to GMG's CEO and managing director, Craig Nicol, has "exceeded the Company's expectations in both graphene production rate and graphene quality. The company continues to perform minor optimizations with this new production plant which have both increased production yield and quality of the graphene".

Researchers develop scalable graphene technology for regulating heat transfer and enhancing battery safety

Researchers at Swansea University, in collaboration with China's Wuhan University of Technology and Shenzhen University, have developed a technique for producing large-scale graphene current collectors that could significantly enhance the safety and performance of lithium-ion batteries (LIBs).

Their recent study details the first successful protocol for fabricating defect-free graphene foils on a commercial scale. These foils offer excellent thermal conductivity - nearly ten times higher than traditional copper and aluminium current collectors used in LIBs.

Danish Graphene completes setup of its battery laboratory

Danish Graphene has announced that its battery laboratory is now fully setup and operational. The Company sees this as a significant milestone, as it now has the capability to produce and test batteries containing graphene, entirely in-house.

With this new battery laboratory, Danish Graphene can manage the whole process internally – from production of individual components to the final assembly of coin cell batteries. This allows the Company to maintain strict quality control and explore new technologies and materials.

Cerebral Energy and Cornell University secure funding for lithium-free aluminum-graphene batteries to support Air Force Special Operations

Cerebral Energy has announced it has been selected by AFWERX (the innovation arm of the U.S Air Force, powered by the Air Force Research Laboratory (AFRL)) for a Phase II STTR follow-on contract in the amount of $1.6 million to support further development of a new lithium-free secondary battery using recycled aluminum and graphene derived from recycled US waste streams.

The technology was developed by Dr. Lynden Archer - Dean of the School of Engineering at Cornell University and licensed by Cerebral. The novel aluminum battery design is over 3X more efficient than lithium, and said to be much safer (no fire risk), 10X faster charging and has no supply chain challenges since the materials are derived from US waste streams. Known as "AGILE," the batteries will first support Air Force Special Operations Command (AFSOC) medical modernization teams to address their pressing tactical power issues.

First Graphene secures funding for a research project with Swansea University to determine the market potential of the Company’s Kainos Technology

First Graphene has secured funding for a collaborative research project with Swansea University to determine the market potential of the Company’s Kainos Technology.

The grant is valued at approximately AU$192,152 (over USD$130,000) and was secured through Analysis for Innovators (A4i) Round 12, Stage 2 funding, delivered by Innovate UK. The funding is specifically meant for businesses utilizing expertise from leading research facilities across the UK to overcome

productivity or technical barriers of new technologies towards market readiness.

Solidion Technology announces that its silicon/graphene anode materials have been validated by an EV OEM-appointed third party

Solidion Technology has announced that its silicon-rich anode material has passed a critical milestone test. The Company stated that its silicon/graphene anode materials have been validated by an EV OEM-appointed third party, that found that its silicon composition is on par with Silane gas-derived Si at a substantially lower cost to EV manufacturers.

The quantity of energy that a lithium-ion battery can supply to an electric vehicle (EV) is limited by the amount of charges stored in its anode and cathode materials. Although graphite has been the preferred anode material during the past 30 years, Industry-leading EV OEMs have reportedly concluded that silicon anode is required to drive EV battery technology to lower cost and provide higher energy density, significantly extending the EV driving range. Specifically, silicon (Si) is a leading-edge anode material capable of extending the EV range by 20-40%. However, the higher-capacity gain is limited by the technical issue of large volume change-induced rapid capacity decay. Additionally, most of the silicon-based anode materials have suffered from processing difficulty using current lithium-ion battery equipment and process.

Salgenx expands potential applications of its graphene and hard carbon-coated sand

Salgenx, developer of saltwater flow battery technology, has announced the expansion of its development of graphene and hard carbon-coated sand. Originally designed for use in advanced battery systems, Salgenx is now exploring a wide array of new applications for this innovative material, ranging from smart infrastructure to environmental sustainability.

The Company says that "the unique combination of graphene and hard carbon in a sand aggregate has the potential to transform the construction industry". By enhancing the electrical conductivity, mechanical strength, and durability of concrete, Salgenx’s carbon-coated sand opens up new possibilities in building and infrastructure development.

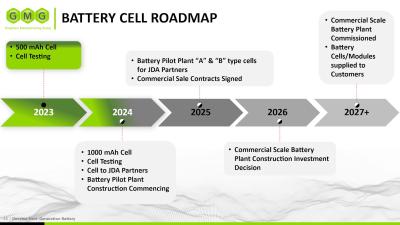

GMG updates on progress with its Graphene Aluminium-Ion Battery

Graphene Manufacturing Group (GMG) has provided a progress update on its Graphene Aluminium-Ion Battery technology ("G+AI Battery") being developed by GMG and the University of Queensland ("UQ").

The Company is currently optimizing the G+AI Battery pouch cell electrochemistry. The challenges that the G+AI Battery are showing through this phase of its maturation are very similar to other battery chemistries that have been developed into mass production - including Lithium-Ion batteries. The performance of the pouch cells will be communicated upon successfully producing a repeatable and 3rd party tested 1000 mAh+ battery pouch cell.

Pagination

- Previous page

- Page 2

- Next page