Graphene thermal conductivity - introduction and latest news

Graphene thermal conductivity

Thermal transport in graphene is a thriving area of research, thanks to graphene's extraordinary heat conductivity properties and its potential for use in thermal management applications.

The measured thermal conductivity of graphene is in the range 3000 - 5000 W/mK at room temperature, an exceptional figure compared with the thermal conductivity of pyrolytic graphite of approximately 2000 W/mK at room temperature. There are, however, other researches that estimate that this number is exaggerated, and that the in-plane thermal conductivity of graphene at room temperature is about 2000-4000 W/mK for freely suspended samples. This number is still among the highest of any known material.

Graphene is considered an excellent heat conductor, and several studies have found it to have unlimited potential for heat conduction based on the size of the sample, contradicting the law of thermal conduction (Fourier's law) in the micrometer scale. In both computer simulations and experiments, the researchers found that the larger the segment of graphene, the more heat it could transfer. Theoretically, graphene could absorb an unlimited amount of heat.

The thermal conductivity increases logarithmically, and researchers believe that this might be due to the stable bonding pattern as well as being a 2D material. As graphene is considerably more resistant to tearing than steel and is also lightweight and flexible, its conductivity could have some attractive real-world applications.

But what exactly is thermal conductivity?

Heat conduction (or thermal conduction) is the movement of heat from one object to another, that has a different temperature, through physical contact. Heat can be transferred in three ways: conduction, convection and radiation. Heat conduction is very common and can easily be found in our everyday activities - like warming a person,s hand on a hot-water bottle, and more. Heat flows from the object with the higher temperature to the colder one.

Thermal transfer takes place at the molecular level, when heat energy is absorbed by a surface and causes microscopic collisions of particles and movement of electrons within that body. In the process, they collide with each other and transfer the energy to their neighbor, a process that will go on as long as heat is being added.

The process of heat conduction mainly depends on the temperature gradient (the temperature difference between the bodies), the path length and the properties of the materials involved. Not all substances are good heat conductors - metals, for example, are considered good conductors as they quickly transfer heat, but materials like wood or paper are viewed as poor conductors of heat. Materials that are poor conductors of heat are referred to as insulators.

How can graphene,s exciting thermal conduction properties be put to use?

Some of the potential applications for graphene-enabled thermal management include electronics, which could greatly benefit from graphene's ability to dissipate heat and optimize electronic function. In micro- and nano-electronics, heat is often a limiting factor for smaller and more efficient components. Therefore, graphene and similar materials with exceptional thermal conductivity may hold an enormous potential for this kind of applications.

Graphene's heat conductivity can be used in many ways, including thermal interface materials (TIM), heat spreaders, thermal greases (thin layers usually between a heat source such as a microprocessor and a heat sink), graphene-based nanocomposites, and more.

Graphmatech and Filalab launch new graphene filament for 3D printing

Swedish material developer Graphmatech and Lithuanian filament manufacturer Filalab UAB recently introduced a new filament called C-PETG. The graphene-enriched material is described as one of the fastest ESD-safe polymer solutions on the market. Developed for the requirements of modern electronics manufacturing, it enables printing speeds of up to 120 mm/s and reliably protects sensitive components from static electricity.

It was stated that C-PETG can print 20% to 120% faster than conventional ESD polymer filaments, which can significantly reduce production time. In addition to speed, the filament is designed to protect sensitive electronic components by effectively dissipating static electricity.

Will Apple's iPhone 17 lineup use graphene cooling tech?

Various reports suggest that the entire iPhone 17 lineup, including the iPhone 17, iPhone 17 Air, iPhone 17 Pro, and iPhone 17 Pro Max, will use a heat dissipation technology called "vapor chamber (VC) cooling system". It is not quite clear, however, which of these models will use combined VC technology and graphene sheets, and which will use only one of these thermal management technologies.

As the iPhone 15 Pro is known to face overheating issues, Apple turned to using graphene sheets in the thermal system when launching the iPhone 16 Pro. To further enhance the cooling mechanism, iPhone 17 models may also adopt vapor chamber technology.

SmartIR’s graphene-based radiator launches on SpaceX Falcon 9

SmartIR, a University of Manchester spinout, has announced that graphene-based adaptive radiator has launched aboard SpaceX’s Falcon 9 Transporter-12 as part of Mission 2, a collaboration with Hydra Space and Alba Orbital.

This mission addresses a critical challenge in the space sector: the need for cost-effective thermal management solutions. Current low-orbit satellites often rely on heaters, which increase power consumption, while long-orbit satellites utilize heavy and bulky systems such as thermal louvres. SmartIR’s graphene-based radiator offers a solution to this problem, enabling satellites to flexibly manage thermal energy. The technology fully vents heat from all surfaces when in Earth’s shadow and selectively shields only the side exposed to the sun during orbit.

New graphene-based laser lift-off process enables ultrathin flexible displays

Researchers from Seoul National University of Science and Technology, Korea Advanced Institute of Science and Technology and Korea Institute of Machinery and Materials recently reported a graphene-based laser lift-off technique that prevents damage while separating ultrathin OLED displays. This advancement could open the door towards ultra-thin, stretchable devices that fit comfortably against human skin, revolutionizing wearable device technology.

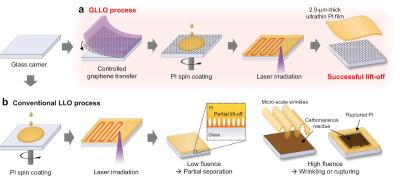

a) Graphene-enabled laser lift-off (GLLO) process. b) Conventional laser lift-off (LLO) process. Image from: Nature Communications

Polyimide (PI) films are widely used in these applications due to their excellent thermal stability and mechanical flexibility. They are crucial for emerging technologies like rollable displays, wearable sensors, and implantable photonic devices. However, when the thickness of these films is reduced below 5 μm, traditional laser lift-off (LLO) techniques often fail. Mechanical deformation, wrinkling, and leftover residues frequently compromise the quality and functionality of ultrathin devices, making the process inefficient and costly.

Researchers develop graphene composite materials for efficient thermal management of Li-ion batteries

Researchers from China's Zhejiang University have developed a new thermal management system to prevent thermal runaway of Li-ion battery (LIB) cells, using hyperbolic graphene phase change composites. This addresses the safety concerns of LIB cells, mainly caused by thermal runaway. While phase change material systems already exist, the unresolved trade-off between high power and energy density greatly limits its practical applications.

The newly developed thermal management system relies on a composite material that consists of hyperbolic graphene framework and paraffin, and reportedly exhibits an impressive thermal conductivity of ∼30.75 W/mK at 12.5 wt% graphene loading and ultrahigh retention (90%) of latent heat, beyond that of most of the reported phase change composites.

Haydale announces steps to improve financial position, including disposal of Korean subsidiary

Haydale Graphene Industries has announced that it has completed a comprehensive business review and unveiled a strategy aimed at achieving near-term profitability while focusing on high-growth opportunities. Haydale said the review, initiated by a reconstituted board following the company's £3.1m funding raise in October, identified key areas for improvement, operational streamlining, and resource reallocation.

Haydale has reportedly decided to focus on two core business lines - heating ink-based energy efficiency products, and carbon capture technology.

Graphene Manufacturing Group demonstrates improved heat sink performance with THERMAL-XR

In a recent PR, Graphene Manufacturing Group (GMG) shared that it continues to advance the commercialization of its THERMAL-XR coating system with the product being tested with companies in multiple industries, including on heat sinks for electronics.

Third-party modelling indicates that applying THERMAL-XR to heat sinks can reduce their size by up to 39% while maintaining the same thermal performance, the company highlighted. This reduction could lead to savings in weight and material costs. The technology also lowers the maximum temperature of heat sinks by 23%, improving their efficiency.

Researchers develop a new process for laser-induced graphene smart textile that could improve space gear

Researchers from the Korea Advanced Institute of Science and Technology (KAIST), Korea Institute of Machinery & Materials and Seoul National University of Science and Technology (SEOULTECH) have shown that laser-induced graphene (LIG), patterned with femtosecond laser pulses, can serve as a versatile material for temperature/strain sensing, stray light absorption, and heat management for smart spacesuits and telescopes.

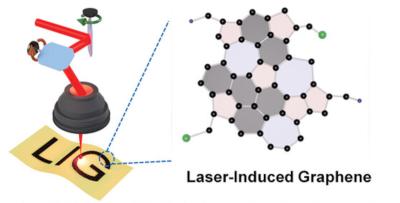

Direct laser writing of laser-induced graphene (LIG). Image from: Advanced Functional Materials

The team has developed a manufacturing technique that addresses the challenges posed by the harsh conditions that space equipment must function in. The scientists' new process uses precisely controlled laser pulses to transform a Kevlar's surface into a porous graphene structure, effectively converting ordinary Kevlar fabric into a multifunctional material.

Solidion develops a graphene-enabled battery fast-charging and cooling system

Solidion Technology has announced that it has been granted a patent on a cost-effective graphene-based strategy for enabling completion of charging in 5 minutes for a wide range of lithium batteries.

Range anxiety, the fear that an electric vehicle (EV) may run out of battery power during a trip, has long been regarded as a key reason for consumers' reluctance to adopt EVs. This issue is exacerbated by the notion that recharging batteries usually takes much longer time than refueling internal combustion engine vehicles (ICEVs). To be competitive with ICEVs, fast charging of EVs should be weather-independent and comparable in time as refueling a gasoline car. Variations in temperatures in different geographic regions and seasons poses a challenge in fast charging EV batteries, since batteries can behave very differently. None of today's EV batteries allow for fast charging at low temperatures.

Graphene Manufacturing Group updates on THERMAL-XR commercialization progress

Graphene Manufacturing Group (GMG) has provided a commercialization update on its THERMAL-XR Powered by GMG Graphene technology, highlighting ongoing customer engagements, testing, and industry recognition.

At a recent event in Brisbane, GMG re-launched its product, now branded as THERMAL-XR ENHANCE, which boasts improved heat transfer and corrosion protection capabilities. In a statement, GMG said that the rebranding from THERMAL-XR RESTORE reflects the product's expanded applications, including enhancing heat transfer in new HVAC equipment, a capability reportedly confirmed through third-party verification.

Pagination

- Page 1

- Next page