Researchers from the Korea Advanced Institute of Science and Technology (KAIST), Korea Institute of Machinery & Materials and Seoul National University of Science and Technology (SEOULTECH) have shown that laser-induced graphene (LIG), patterned with femtosecond laser pulses, can serve as a versatile material for temperature/strain sensing, stray light absorption, and heat management for smart spacesuits and telescopes.

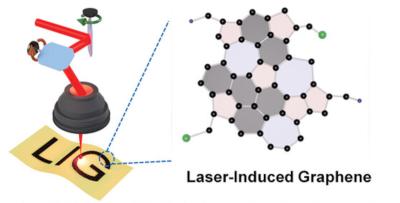

Direct laser writing of laser-induced graphene (LIG). Image from: Advanced Functional Materials

The team has developed a manufacturing technique that addresses the challenges posed by the harsh conditions that space equipment must function in. The scientists' new process uses precisely controlled laser pulses to transform a Kevlar's surface into a porous graphene structure, effectively converting ordinary Kevlar fabric into a multifunctional material.

The key to this material's performance lies in its microscopic structure. The laser creates a forest-like network of graphene, with countless tiny pores and channels. This structure traps and absorbs 97.57% of incoming light across visible and infrared wavelengths – significantly better than traditional black coatings used in telescopes.

The same porous network also conducts heat rapidly, moving it six times faster than standard telescope materials. This combination prevents both light interference and temperature-related distortions that can degrade telescope images.

When used as a sensor, the material detects temperature changes with three times the sensitivity of current space suit sensors. It responds to physical movement with 454 times the electrical response of basic strain sensors, enabling precise monitoring of an astronaut's motion and vital signs without bulky electronics.

The manufacturing process offers precise control over the graphene formation. The laser can create specific patterns optimized for different functions – from networks of health monitoring sensors to large surfaces that absorb stray light. By working directly with Kevlar, already standard in space equipment, the technique simplifies integration into existing systems.

The research team validated their material through rigorous space-environment testing. They placed samples in a vacuum chamber at one-millionth of normal atmospheric pressure – similar to conditions in low Earth orbit. For 40 hours, they cycled the temperature between -20 and 60 degrees Celsius, matching the temperature swings that occur as spacecraft move between sunlight and shadow. The material maintained its sensing capabilities and optical properties throughout these tests.

This single material platform could replace multiple specialized systems in space equipment. Space suits incorporating this modified Kevlar could monitor astronaut health more effectively while remaining flexible. Telescopes could achieve clearer images through better control of stray light and temperature fluctuations, without requiring separate systems for each function.

Before space deployment, the material requires additional testing under radiation exposure and actual space conditions. The manufacturing process needs scaling up from laboratory to production quantities. The researchers are particularly focused on testing long-term stability and developing automated manufacturing methods.

The technique demonstrates how advanced materials can simplify space systems by combining multiple functions in a single platform. By reducing complexity while improving performance, this approach could influence how engineers design future space exploration equipment.