GrapheneUP®, an industry vanguard in manufacturing verified few-layer graphene and a diverse array of graphene-centric intermediary products, announces the debut of MASTERGUP® — an innovative line of thermoplastic masterbatches. This breakthrough harnesses the transformative potential of graphene, setting a new benchmark for sustainability and recyclability within multiple sectors.

Graphene, distinguished by its exceptional strength and conductivity, imparts enhanced thermoplastic properties, including mechanical robustness, thermal stability, and gas barrier properties. These advancements extend the lifespan of products and significantly reduce waste, thereby contributing to more excellent environmental stewardship. Moreover, incorporating the graphene GUP® into thermoplastic matrices elevates processability, streamlining the molding, reshaping, and recycling processes. GUP®-fortified thermoplastics demonstrate remarkable endurance through repeated recycling, mitigating material degradation — a commendable achievement in material sustainability.

GrapheneUP®'s three-year R&D initiative has culminated in the optimal graphene functionalization and dispersion processes, featuring a proprietary technique that ensures homogenous distribution, leveraging the full potential of high-quality graphene.

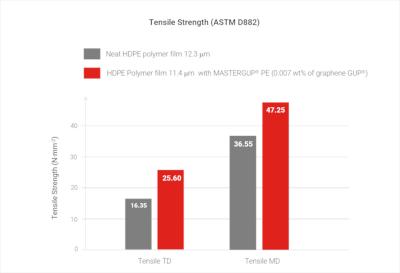

Currently, the product line MASTERGUP® caters to polymers such as polypropylene, polyethylene, polyamide, and polylactic acid. The specific properties of the graphene GUP®, characterized by a high carbon-to-oxygen ratio and significant lateral dimensions — the largest presently available in the market — means that even minimal concentrations can dramatically enhance the mechanical and thermal properties of thermoplastic polymers and with outstanding oxygen and hydrogen barrier properties. Client testing confirms that concentrations of graphene GUP® as low as 0.006-0.008 wt% can increase tensile strength in HDPE films by over 50% and improve dart impact resistance by 31%.

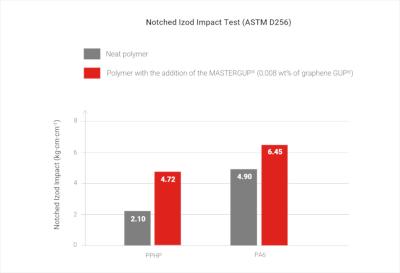

The resistance to impact is another essential property improved. The Notched Izod Impact test showed an improvement of over 124% with a concentration of 0.008 wt% of graphene GUP® in PPHP.

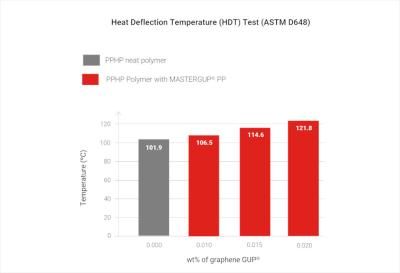

The graphene GUP®'s large lateral size and low defects make it a candidate for the most demanding thermal management applications. At a concentration of 0.02 wt% of GUP®, one client measured an increase of about 20 degrees in polypropylene polymer in the Heat Deflection Temperature (HDT) Test.

GrapheneUP® is actively engaged in pioneering real-world applications of graphene within the automotive sector, as well as in the production of packaging materials, stretch films and shopper bags, illustrating the versatile applicability of our MASTERGUP® technology.

The strategic implementation of MASTERGUP® PE into shopper bags manufactured for a renowned retail entity has manifested in marked improvements in tensile and impact strength, alongside enhanced overall resilience. This superior formulation facilitated a 24% reduction in material thickness, leading to a sturdier, eco-friendly bag and a corresponding 24% decrease in annual plastic consumption, highlighting a significant stride towards environmental sustainability.

Further, MASTERGUP® has been rigorously tested and validated in enhancing stretch films. The outcome is a line of films boasting increased tensile strength, augmented durability, and improved resistance to puncturing. The utilization of MASTERGUP® has simultaneously reduced the volume of plastic required, as the films maintain their integrity even with a reduced gauge, thus contributing to a lesser environmental footprint.

GrapheneUP® also produces tailored GUP®-based thermoplastic masterbatches designed to meet specific customer requirements. In addition, the company offers bespoke GUP®-based additives, empowering companies to make their proprietary masterbatches in-house, fostering innovation and self-sufficiency in applying graphene-enhanced products.

GrapheneUP® stands at the forefront of graphene innovation, charting a course toward a resilient, resource-efficient future where sustainable practices are seamlessly integrated with industrial advancement. Through MASTERGUP®, the company is committed to propelling industries toward their sustainability goals, fostering a synergistic relationship between responsible manufacturing and the circular economy.

This was a sponsored post by GrapheneUP