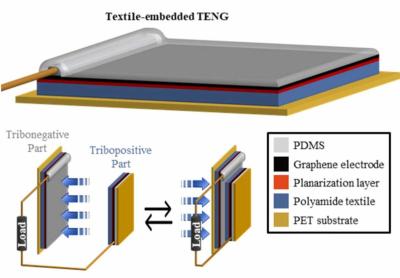

Researchers from Portugal's Instituto de Engenharia de Sistemas e Computadores – Microsistemas e Nanotecnologias (INESC MN), Universidade de Lisboa and the UK's University of Exeter have developed an efficient flexible triboelectric textile by using printed graphene electrodes with polydimethylsiloxane (PDMS) and the textile itself as the triboelectric pair.

To achieve this, the team used a textile planarization technique with a polyurethane adhesive, along with three different deposition methods: graphene droplet films (GDF), graphene immersion films (GIF), and graphene spray films (GSF).

The result was a flexible textile electrode that surpassed non-planarized devices in all three printing techniques, with a 4-fold improvement and a power density of 3.08 µW/cm². Moreover, by increasing the TENG contact area through the use of four parallel devices measuring 3 × 3 cm² each, the power output reached an effective power of 60 µW.

The flexible TENG is said to present a stable output performance under strong deformation and its sensitivity to movement was explored as wearable sensor to monitor biomechanical movements.

This work describes a versatile method for constructing flexible triboelectric textile fabrics using only industrial compatible printing textile processes, paving the way to the seamless integration of self-powered wearable sensing technology into textiles.