Researchers use graphene to create detachable flexible microLED devices

University of Texas at Dallas researchers and their international colleagues have developed a graphene-based method to create micro LEDs that can be folded, twisted, cut and stuck to different surfaces. The research could help pave the way for the next generation of flexible, wearable technology.

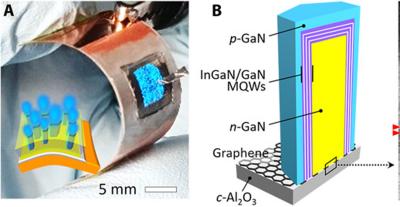

(A) Photograph of EL light emission from MR LED in a bent form. (B) Cross-sectional schematic of MR heterostructures grown on graphene-coated c-Al2O3 wafer. Image from Science Advances

(A) Photograph of EL light emission from MR LED in a bent form. (B) Cross-sectional schematic of MR heterostructures grown on graphene-coated c-Al2O3 wafer. Image from Science Advances

Used in various applications like signage and automotive lights, LEDs are ubiquitous because they are lightweight, thin, energy efficient and visible in different types of lighting. Micro LEDs, which can be as small as 2 micrometers and bundled to be any size, provide higher resolution than LEDs. Their size makes them a good fit for small devices such as smart watches, but they can be bundled to work in flat-screen TVs and other larger displays. LEDs of all sizes, however, are brittle and typically can only be used on flat surfaces. The researchers’ new micro LEDs aim to enable bendable, wearable electronics.